| Genuine P&H Parts Available |

||

|

1007Z375 |

SAFETY LATCH |

|

|

100E1076-1 |

MAGNET ASSEMBLY |

|

|

100E2397-2 |

PUSH BUTTON |

1 SPEED |

|

100E2504-1 |

SWITCH ASSEMBLY |

|

|

100E2783-4 |

INTERLOCK |

|

|

100E2783-6 |

INTERLOCK |

|

|

100E4438-1 |

SWITCH |

|

|

100E4537-2 |

PUSH BUTTON |

5 SPEED |

|

100E4538-2 |

PUSH BUTTON |

2 SPEED |

|

100E4966-3 |

BRAKE RECTIFIER |

|

|

100E6558-1 |

INTERLOCK |

|

|

100E695-7 |

LIMIT SWITCH ASSEMBLY |

|

|

100F682-2 |

SWITCH |

|

|

1014Z2805 |

COVER |

|

|

1014Z3145 |

GEAR CASE ASSEMBLY |

|

|

1016Z948 |

HANGER ANCHOR |

|

|

1017Z1 |

SPRING |

|

|

1018Z6333 |

SNAP RING |

|

|

1010Z11231 |

ROD END |

|

|

1045Z666 |

BRAKE REPAIR KIT |

|

|

1045Z87 |

SPRING W/ CASE |

|

|

1048Z22 |

SEAT CUSHION |

|

|

1075Z1611 |

TRANSISTOR MODULE |

|

|

1079Z1215 |

CONTACT KIT |

|

|

1079Z1217 |

CONTACT |

|

|

1079Z213 |

TIP |

|

|

1079Z2159 |

CONTACT |

|

|

1079Z4511 |

CONTACT KIT |

|

|

1079Z4512 |

CONTACT KIT |

|

|

1079Z4513 |

CONTACT KIT |

SIZE 1-3/4 |

|

1079Z4519 |

CONTACT KIT |

|

|

1079Z4522 |

CONTACT KIT |

SIZE 2 |

|

1079Z4524 |

CONTACT KIT |

|

|

1079Z4550 |

MOVABLE CONTACT |

|

|

1079Z4551 |

STATIONARY CONTACT |

|

|

1079Z4552 |

STATIONARY CONTACT |

|

|

1079Z606 |

CONTACT |

|

|

10F9079D1 |

SHAFT |

13" SBE |

|

10F9105D5 |

SHAFT |

|

|

1100F2-2 |

SHAFT / FLANGE KIT |

|

|

100H37-1 |

REPAIR KIT FOR 100J4109-1 HYDRAULIC CYLINDER |

|

|

1100T179-1 |

SEAL REPAIR KIT |

|

|

110E81F7 |

CONTACT BLOCK |

|

|

13F1879D1 |

BRAKE WHEEL |

10" |

|

13Z333 |

WHEEL |

|

|

13Z403 |

ROLLER |

|

|

14H493 |

WASHER |

|

|

14Q94 |

JUNCTION BOX |

|

|

15F388 |

ROD |

|

|

15F391C2 |

LINING |

|

|

15F427 |

DISC PLATE |

|

|

15F486 |

PIVOT LINK |

|

|

15F518 |

DISC |

|

|

15Q6 |

DISC |

|

|

15Q87D1 |

FRICTION DISC |

|

|

15Q91D1 |

BRAKE DISC |

|

|

15Q93D1 |

FRICTION DISC |

|

|

15U78D2 |

BRAKE |

|

|

16Z119 |

SUPPORT |

|

|

16Z509D1 |

BUMPER |

|

|

17H124 |

SPRING |

|

|

17H126 |

SPRING |

|

|

17H128 |

SPRING |

|

|

17H218 |

SPRING |

|

|

17H281 |

SPRING |

|

|

17H317 |

SPRING |

|

|

17H327 |

SPRING |

|

|

17H401 |

SPRING |

|

|

17H451 |

SPRING |

|

|

17Q22 |

SPRING |

|

|

17Z103 |

SPRING |

|

|

17Z140 |

SPRING |

|

|

17Z147 |

SPRING |

|

|

17Z161D1 |

SPRING |

|

|

17Z165 |

SPRING |

|

|

17Z174 |

SPRING |

|

|

17Z183 |

SPRING |

|

|

17Z222 |

SPRING |

|

|

17Z286D13 |

SPRING WASHER |

|

|

17Z286D14 |

WASHER |

|

|

17Z286D15 |

SPRING WASHER |

|

|

17Z286D17 |

WASHER |

|

|

17Z286D20 |

SPRING WASHER |

|

|

17Z286D46 |

WASHER |

|

|

17Z294 |

SPRING |

|

|

17Z397 |

SPRING |

|

|

17Z403 |

SPRING |

|

|

17Z548D1 |

SPRING W/ PLATE |

|

|

17Z548D2 |

SPRING W/ PLATE |

|

|

17Z548D3 |

SPRING W/ PLATE |

|

|

17Z548D5 |

SPRING W/ PLATE |

|

|

17Z652 |

SPRING |

|

|

17Z760 |

SPRING |

|

|

17Z797 |

SPRING |

|

|

17Z888 |

COMPRESSION SPRING |

|

|

17Z942 |

SPRING |

|

|

17Z944 |

SPRING |

|

|

18F1825 |

SPACER |

|

|

18F1866D1 |

SPACER |

16" SBE BRAKE |

|

18F1866D2 |

SPACER |

|

|

18F1866D3 |

SPACER ARMATURE |

19" SBE BRAKE |

|

20F315 |

BRAKE ROD |

|

|

20H4195 |

BRAKE STUD |

|

|

278F1559D1 |

SHOE |

|

|

301F1037F2 |

SHAFT |

D FRAME |

|

301F1068C1 |

PINION |

|

|

301F1069C1 |

PINION |

|

|

301F1233 |

PINON GEAR |

|

|

301F1375 |

PINION |

|

|

301F1423 |

PINION GEAR |

|

|

301F1448 |

PINION |

|

|

301F1527F1 |

SHAFT |

|

|

301F298F1 |

PINION ASSEMBLY |

|

|

301F288F1 |

PINION ASSEMBLY |

|

|

301F829 |

GEAR |

|

|

301F888D2C1 |

DRUM GEAR |

|

|

301F889F2 |

SHAFT |

|

|

301H569 |

GEAR |

|

|

301H588 |

INTERMEDIATE PINION |

|

|

301H595 |

PINION |

|

|

307F228C1 |

SHEAVE |

|

|

307F229C1 |

SHEAVE |

|

|

307F236 |

SHEAVE |

|

|

307F91 |

SHEAVE |

|

|

307H54C1 |

SHEAVE |

|

|

301F1124F1 |

HOOK |

|

|

308F1127F1 |

HOOK ASSEMBLY |

|

|

308F1136F0 |

HOOK ASSEMBLY |

|

|

308F1144 |

HOOK |

|

|

308F564 |

HOOK |

|

|

308F724F1 |

HOOK |

|

|

308F868F1 |

HOOK ASSEMBLY |

|

|

30Z120F1 |

CABLE ASSEMBLY |

|

|

30Z120F2 |

CABLE |

|

|

30Z120F4 |

CABLE |

|

|

30Z121F2 |

CABLE ASSEMBLY |

|

|

30Z140F2 |

CABLE |

|

|

3100E771-1 |

BRAKE |

|

|

3100F686-8 |

GEAR CASE |

|

|

310H277F1 |

SHAFT ASSEMBLY |

|

|

310H508F1 |

SHAFT |

|

|

313F1151 |

RATCHET ASSEMBLY |

|

|

313F1161 |

RATCHET ASSEMBLY |

|

|

313F352 |

HUB |

|

|

313F488 |

HUB |

|

|

313F596 |

HUB |

|

|

313F665 |

HUB |

|

|

313F799 |

HUB |

|

|

313F907 |

TRUCK WHEEL IDLER |

|

|

314A141 |

GEAR CASE |

|

|

314F356 |

COVER |

|

|

314F626 |

COVER |

|

|

315F133 |

PLATE |

|

|

315F134 |

PLATE |

|

|

315F136 |

PLATE |

|

|

315F138 |

PLATE |

|

|

315F140 |

DISC PLATE |

|

|

315F193 |

DISC |

|

|

315F196 |

FRICTION DISC |

|

|

315F198 |

FRICTION DISC |

|

|

315F200 |

FRICTION DISC |

|

|

315F27D2 |

DISC PLATE |

|

|

315F74C2 |

DISC |

|

|

318F1897F2 |

COUPLING |

|

|

318F1898F2 |

COUPLING |

|

|

318F1900F2 |

COUPLING |

|

|

318F1901F2 |

COUPLING |

|

|

318H1880C1 |

COUPLING |

|

|

318H1900C1 |

COUPLING |

|

|

318H1909C1 |

COUPLING |

|

|

318H1925C1 |

COUPLING |

|

|

318H1926C1F1 |

COUPLING |

|

|

318H1964 |

DRUM SLEAVE |

|

|

318H2000 |

DRUM SLEAVE |

|

|

318H2040 |

DRUM SLEAVE |

|

|

6100E429F1 |

BOTTOM BLOCK ASSEMBLY |

|

|

6988E401-5 |

MOTOR |

|

|

73Q5 |

BRUSH HOLDER |

|

|

73Q6 |

BRUSH HOLDER |

|

|

73Q7 |

BRUSH HOLDER |

|

|

73Q8 |

BRUSH HOLDER |

|

|

75Q336D1 |

TRANSFORMER |

|

|

75Z1091D1 |

RECTIFIER |

|

|

75Z23D1 |

TRANSFORMER |

|

|

75Z331D1 |

RECTIFIER |

|

|

75Z456D3 |

RECTIFIER |

|

|

75Z514D1 |

TRANSFORMER |

|

|

75Z578D1 |

RECTIFIER |

|

|

75Z578D4 |

RECTIFIER |

|

|

75Z57D1 |

TRANSFORMER |

|

|

75Z590D13 |

DIODE |

|

|

78F247F1 |

WHEEL |

|

|

78F294 |

SHOE |

|

|

78H237 |

INSULATOR |

|

|

78H243 |

BRACKET |

|

|

79F1435C1 |

SHIELD |

|

|

79H1042C1 |

ARC SHIELD |

|

|

79H1043C1 |

ARC SHIELD |

|

|

79H1125 |

CONTACT |

|

|

79H1356 |

CONTACT SUPPORT |

|

|

79H1456D1 |

CONTACT STATIONARY |

|

|

79H1457D1 |

CONTACT |

|

|

79H1458 |

INSULATOR |

|

|

79H1586D2 |

CONTACT |

|

|

79H1606 |

CONTACT |

|

|

79H1607 |

CONTACT |

|

|

79H1683 |

TIP |

|

|

79H1684 |

TIP |

|

|

79H1833 |

TERMINAL BAR |

|

|

79H1922 |

CONTACT |

|

|

79H2017C1 |

SWITCH |

|

|

79H2171 |

TIP |

|

|

79H2181 |

TIP |

|

|

79H583 |

INSULATOR |

|

|

79H618 |

BAR |

|

|

79H734 |

CONTACT TIP |

|

|

79Q1050D5 |

CONTACT BLOCK |

|

|

79Q1050D7 |

CONTACT BLOCK |

|

|

79Q1051D3 |

RELAY |

|

|

79Q1052D1 |

CONTACTOR |

|

|

79Q1056D1 |

RELAY |

|

|

79Q1057D4 |

CONTACTOR |

|

|

79Q638 |

CONTACTOR |

|

|

79R453D501 |

FUSE |

|

|

79U10D2 |

MODULE |

|

|

79U2485D1 |

BRAKING MODULE |

|

|

79U2488D2 |

INTERFACE BOARD |

|

|

79U6D3 |

MODULE |

|

|

79Z1738D2 |

CABLE GUIDE |

|

|

79Z2475D1 |

NETWORK |

|

|

79Z264D20 |

TIMER |

|

|

79Z3145 |

CONTACT TIP |

|

|

79Z3253D2 |

RELAY |

|

|

79Z3293 |

LIMIT SWITCH |

|

|

79Z602D1 |

HOOD, BLACK |

|

|

79Z602D2 |

HOOD, GREEN |

|

|

79Z602D3 |

HOOD, RED |

|

|

79Z602D4 |

HOOD, ORANGE |

|

|

79Z602D5 |

HOOD, YELLOW |

|

|

79Z602D2 |

HOOD, BLUE |

|

|

79Z95D5 |

FUSE |

|

|

79Z994D4 |

RELAY |

|

|

80F386D4 |

SEGMENT |

|

|

80F387D13 |

SEGMENT |

|

|

80F387D14 |

SEGMENT |

|

|

80F387D2 |

SEGMENT |

|

|

80F387D3 |

SEGMENT |

|

|

80F387D4 |

SEGMENT |

|

|

80H679 |

|

|

|

80H681 |

CAM |

|

|

80H682 |

CAM |

|

|

80H684 |

CAM |

|

|

80H961 |

CONTACT |

|

|

80Q35D5 |

VARISTOR |

|

|

80Z117 |

SCREW |

|

|

815E1601 |

ARMATURE PLATE |

|

|

815E1608 |

DISC |

|

|

818H1447 |

BUSHING |

|

|

819H67D37 |

DRIVE LOCK PIN |

|

|

81A55 |

ARMATURE |

|

|

81 E44 |

ARMATURE |

|

|

81E83D1 |

ARMATURE PLATE |

|

|

81F82C1 |

ARMATURE |

|

|

81H109 |

CLAMP |

|

|

81H115 |

CLAMP |

|

|

81H13 |

CLAMP |

|

|

81H50 |

CLAMP |

|

|

81H59 |

CLAMP |

|

|

820F1517 |

BRAKE STUD |

|

|

820H1601D1 |

GASKET |

|

|

85Z24D8 |

CORD GRIP |

|

|

87H43 |

COVER |

|

|

87Z23 |

RECEPTACLE |

|

|

88Z390D10 |

MOTOR |

|

|

8Z388D3 |

LATCH KIT |

|

|

8Z388D5 |

LATCH KIT |

|

|

8Z388D6 |

LATCH KIT |

|

|

8Z64D17 |

LATCH KIT |

|

|

8Z64D21 |

LATCH KIT |

|

|

8Z64D25 |

LATCH KIT |

|

|

8Z64D27 |

SAFETY LATCH |

|

|

8Z64D3 |

LATCH KIT |

|

|

8Z64 D7 |

LATCH KIT |

|

|

8Z64D9 |

LATCH KIT |

|

|

9085-1 |

SHUNT |

|

|

914F85-3 |

TOP COVER ASSEMBLY 6 HOLE P.B. |

|

|

914F85-4 |

FRONT COVER 8 HOLE P.B. |

|

|

914F86-4 |

BACK COVER 8 HOLE P.B. |

|

|

915F71-1 |

BRAKE SHOE |

|

|

915F73-1 |

BRAKE SHOE |

|

|

915F84-1 |

BRAKE SHOE |

|

|

915F84-4 |

BRAKE SHOE |

|

|

9308F115-28 |

CABLE |

|

|

9308F32-33 |

CABLE |

|

|

9308F41-1 |

CABLE |

|

|

9308H112-1 |

CABLE |

|

|

9308H112-2 |

CABLE |

|

|

9308H129-1 |

CABLE |

|

|

9308H129-2 |

CABLE |

|

|

9308H168-1 |

CABLE |

|

|

9308H174-1 |

CABLE |

|

|

9308H48-5 |

CABLE |

|

|

9310F102-4 |

DRUM PINION LEFT HAND |

|

|

9310F122-4 |

DRUM PINION LEFT HAND |

|

|

9310F123 |

DRUM PINION |

|

|

9318H31-1 |

SPRING |

|

|

9318HH31-2 |

SPRING |

|

|

9318H31-4 |

SPRING |

|

|

9325H48-1 |

BEARING ASSEMBLY |

|

|

9398-1 |

SUPPORT |

|

|

9601E410F1 |

LIMIT SWITCH ASSEMBLY |

|

|

9601E410F2 |

SWITCH DRIVE SHAFT ASSEMBLY |

|

|

9679F401-1 |

LIMIT SWITCH ASSEMBLY |

|

|

9681E402F1 |

BRAKE SOLENOID & PLATE |

|

|

973F83-1 |

BRUSH HOLDER ASSEMBLY |

|

|

973F91-3 |

BRUSH HOLDER ASSEMBLY |

|

|

975E47-12 |

POT ASSEMBLY |

|

|

975E632-2 |

COIL |

|

|

979E269-1 |

ARC SHIELD |

|

|

979H101-1 |

CONTACT |

|

|

979H99-1 |

CONTACT |

|

|

981A6-4 |

POT ASSEMBLY |

|

|

981A7-4 |

POT ASSEMBLY |

|

|

981E48-2 |

POT ASSEMBLY |

|

|

9314E91-1 |

GEAR CASE COVER |

E FRAME |

|

9314E98-1 |

GEAR CASE COVER |

D FRAME |

|

981A5-10 |

MAGNETIC POT ASSEMBLY 100 VOLT |

CD-5 |

|

981A5-2 |

MAGNETIC POT ASSEMBLY 18 VOLT |

CD-5 |

|

F386D3 |

SEGMENT |

|

|

F387D4 |

SEGMENT |

|

|

R24286 D1 |

BRAKE DISC |

HEVI-LIFT HOIST |

|

R24288 D1 |

BRAKE DISC |

HEVI-LIFT HOIST |

|

SURPLUS MOTORS |

||

|

MOTOR |

7-1/2 HP 1145 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 324 FRAME TENV |

|

|

MOTOR |

10 HP P&H 1750 RPM SINGLE SPEED HOIST MOTOR 230/460 VOLT FRAME S250 UY TYPE SCTA SINGLE BEARING W/ SPLINED OUT PUT SHAFT FLANGE MOUNT TO FIT HEVI-LIFT HOIST |

|

|

MOTOR |

20 HP 1145 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 326X FRAME TENV |

|

| MOTOR |

25 TON 1710 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 324 ROUND FRAME SINGLE BEARING W/ SPLINED OUTPUT SHAFT FLANGE MOUNT TO FIT HEVI-LIFT HOIST |

|

| MOTOR | 40 HP 1750 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 365X FRAME TENV | |

| MOTOR | 25 HP 1710 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 324 FRAME TENV | |

| MOTOR | 60 HP 1130 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 365 XL | |

| MOTOR | 75 HP 1150 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 444 X TENV | |

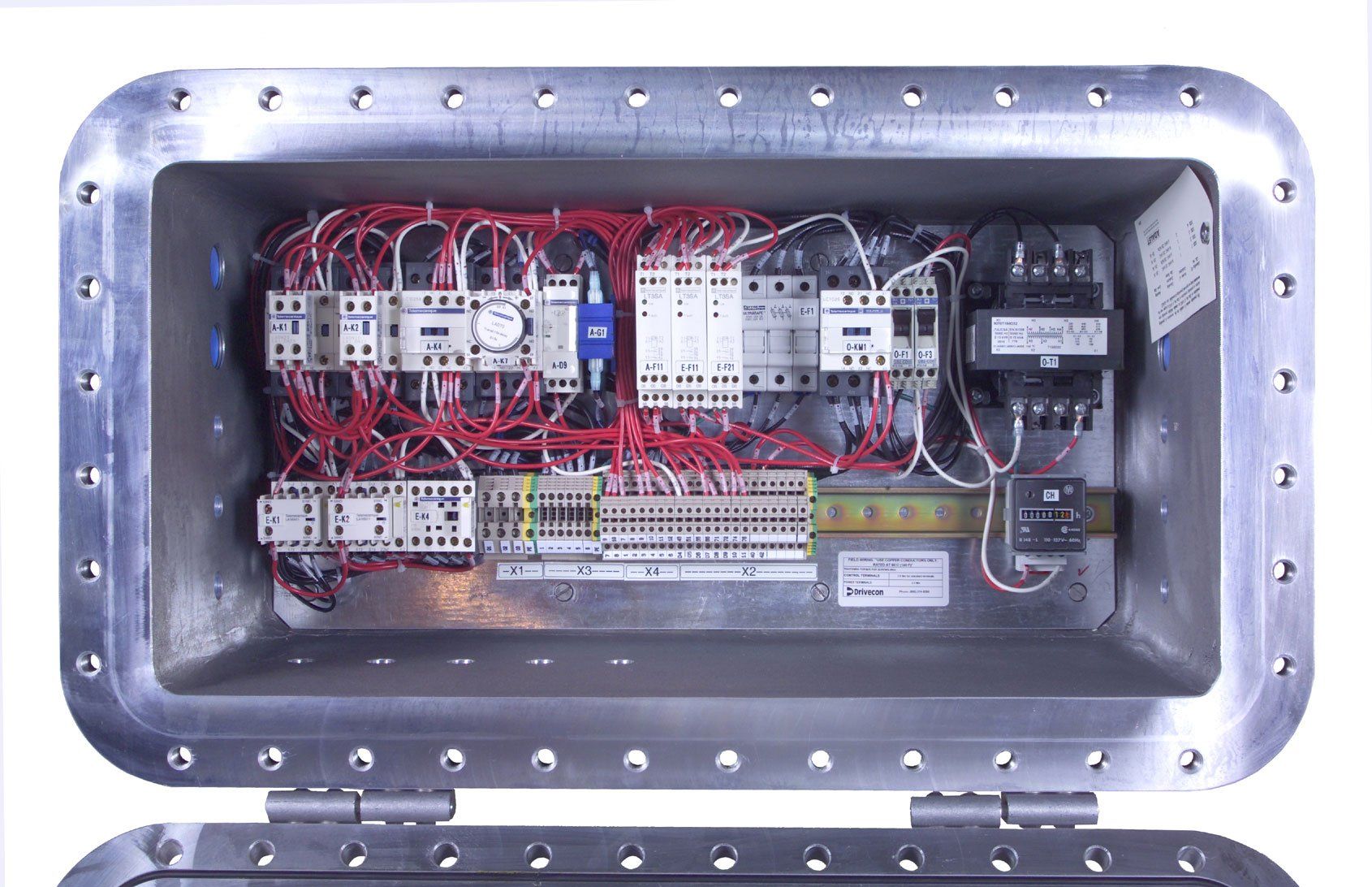

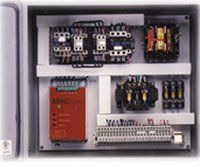

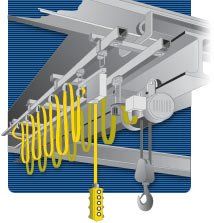

Components

ELECTRIFICATION

| Omnipulse DC Hoist

Controls

|

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Omnipulse

DC Bridge & Trolley Controls

|

|||||||||||||||||||||||||||||||||||||||||||||

Supply voltages: 200-300 Volts

DC. Nominal low voltage operation down to 100 volts.

Motor Type: DC Series -Wound

Control Range: 0-100%

Operating Frequency:

2kHz�10kHz

Logic Type: Microprocessor

Digital Logic

|

|||||||||||||||||||||||||||||||||||||||||||||

| Model | MAC��2000 |

| Voltage Rating |

|

| Application | Single- or Two-Speed |

| Duty Cycle | CMAA Class "D" Service |

| Frequency | 50/60 Hz |

| Overload Capacity |

|

| Ambient Temperature | 14� to 104�F (-10� to +40�C) |

| Dimensions-In Inches | 4.12" (W) x 7.18" (H) x 2.62" (D) |