A Resource Library of Our Products and Services

Hoists & Parts

- Yale Hoists

Yale Hoists

Chain Hoists, Wire Rope Hoists, Air Hoists, Crane Components

There's a Yale product for every lifting job.

Yale variety lets you match your hoist to the job for maximum dollar value. Hoists in the Yale line are quality engineered and performance tested before they are shipped to you. That's why the Yale name has stood for quality for over 100 years.

Look up to Yale for excellence in hoisting equipment.

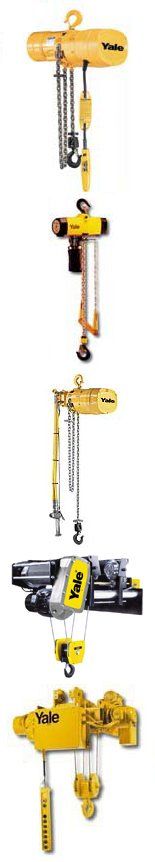

Chain Hoists

- Electric - 300 lbs to 3 tons

- Air - 1/4 to 6 tons

- Manual - 1/4 to 50 tons

- Low Headroom - 1/4 to 24 tons

- Army Type - 1/4 to 12 tons

- Spark Resistant

Lever Hoists

- Aluminum Frame - 3/4 to 6 tons

- Malleable Iron Frame - 3/4 to 15 tons

- Steel Frame - 3/4 to 6 tons

- Wire Rope Pullers - 1/2 to 1 ton

Trolleys

- Push - 1/4 to 50 tons

- Hand Geared - 1/4 to 50 tons

- Motorized - 1/4 to 3 tons

- Hook Mount - 1/4 to 50 tons

- Lug Mount - 1/4 to 3 tons

- Tractor Drives - 1/4 to 5 tons

- Spark Resistant

Global King Wire Rope Hoist

- 5, 7 1/2 & 10 ton models

- Metric capacity rated

- Low headroom design for maximum lift

- Designed for H4 service minimum

- Electrics to N.E.C. standards

- 2-speed hoists & trolleys

- NEMA 4/12 panel

- 6:1 ratio on hoist, 3:1 on trolley, high to low speeds

- Upper / lower geared limit switch

- Upper block operated limit switch

- Runs on beam flanges 4 5/8”- 20” wide; on beams to 2” thick

- Hoist gearing in separate, easily accessible gear case

Wire Rope Hoists

- 1/2 to 35 ton capacity

- Electric

- Air Operated

- Low Headroom

- Spark Resistant

- Explosion Proof

Top-Running Trolleys

- 5 to 35 ton capacity

- Electric

- Air Operated

- Spark Resistant

- Explosion Proof

Crane Components

- 1 to 35 ton capacity

- Top-Running

- Under-Running

- Single Girder

- Double Girder

- Electric

- Air Operated

- Spark Resistant

- Explosion Proof

Other Yale products (not shown)

- Jib Cranes

- Test Stands

Contact Milwaukee Crane for assistance and product information on Yale Hoists.

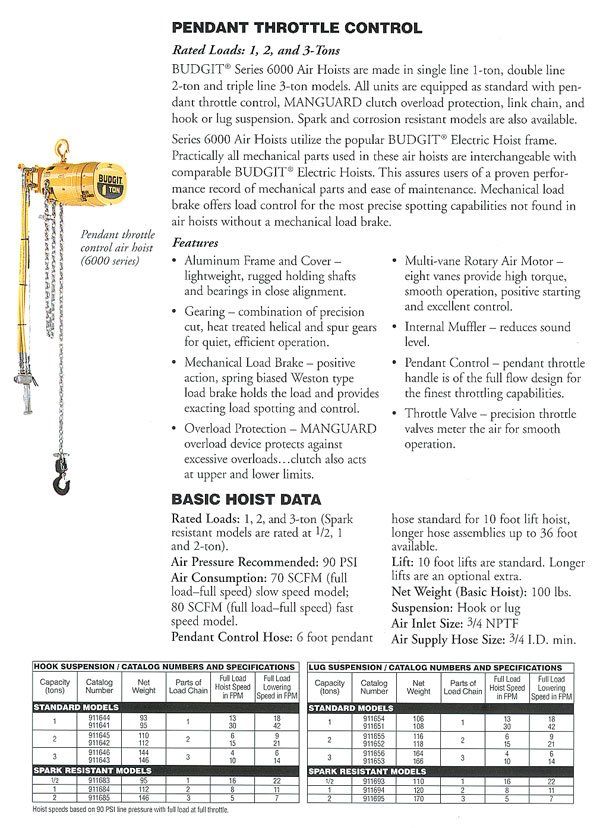

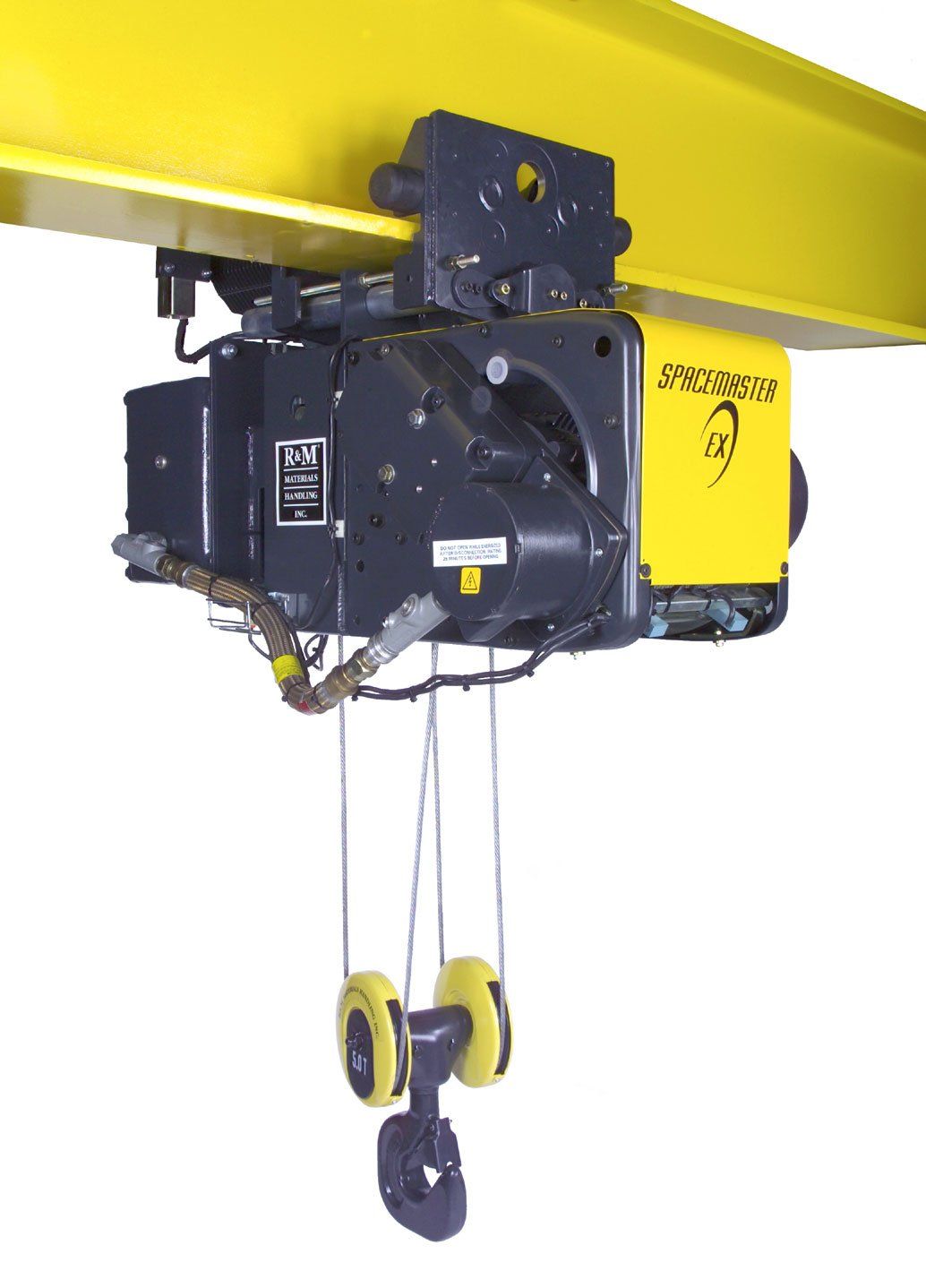

- Budgit Hoists

Budgit Hoists

There's a Budgit Hoist for Every Job.

Budgit Hoists: Tough jobs demand tough Budgit hoists.

For over 60 years, BUDGIT� Chain Hoists have been designed and manufactured for tough jobs.

Since 1935, BUDGIT� has led the industry in innovation, quality and dependability. These compact, lightweight, economical hoists are built to withstand the rigors of heavy service and repeated lifting cycles.

They are easy to service, require minimal maintenance and offer excellent headroom.

Budgit Chain Hoists

- Electric - 300 lbs to 7-1/2 tons

- Air - 1/4 to 3 tons

- Manual - 1/4 to 50 tons

- Army Type - 1/4 to 12 tons

- Low Headroom - 1/4 to 24 tons

- Swivel Truck - 1/4 to 6 tons

- Twin Hook - 1/2 to 10 tons

- Spark Resistant

Lever Hoists

- Tugit�2 Aluminum Frame - 3/4 to 6 tons

- Steel Frame - 3/4 to 6 tons

- Wire Rope Pullers - 1/2 to 1 ton

Trolleys

- Push - 1/4 to 50 tons

- Hand Geared - 1/4 to 40 tons

- Motorized - 1/4 to 7-1/2 tons

- Hook Mount - 1/4 to 50 tons

- Lug Mount - 1/4 to 7-1/2 tons

- Tractor Drives - 1/4 to 5 tons

- Spark Resistant

Crane Components

- Under-Running End Trucks & Kits - 1/4 to 5 tons, spans to 36'

- Top-Running End Trucks & Kits - 1/4 to 5 tons, spans to 36'

- Spark Resistant

Other Budgit products (not shown)

- Articulating Jib Cranes

- Test Stands

Please contact Milwaukee Crane's expert staff for applications assistance for Budgit Hoist products.

- C M Lodestar Hoists

CM Hoists

Chain and Wire Rope Hoists - Electric and Pneumatic

CM hoists are manufactured by Columbus McKinnon Corporation, a leading designer and manufacturer of material handling products, systems and services which efficiently and ergonomically move, lift, position or secure material.

CM AirStar 6 Air Hoist

Designed for general industrial applications where variable speed pneumatic power is preferable. Rated for loads of up to 3 tons. This compact, lightweight hoist features:

- Lightweight aluminum frame and cover

- Positive action, spring biased Weston-type load brake holds the load, provides exacting load spotting and control

- Multi-vane rotary air motor with eight vanes for high torque, smooth operation, positive starting

- Precision cut heat treated helical and spur gear combination for quiet, efficient operation

- Pendant throttle handle is full flow design for precision throttle capabilities

- Lifetime warranty

- Made in U.S.A.

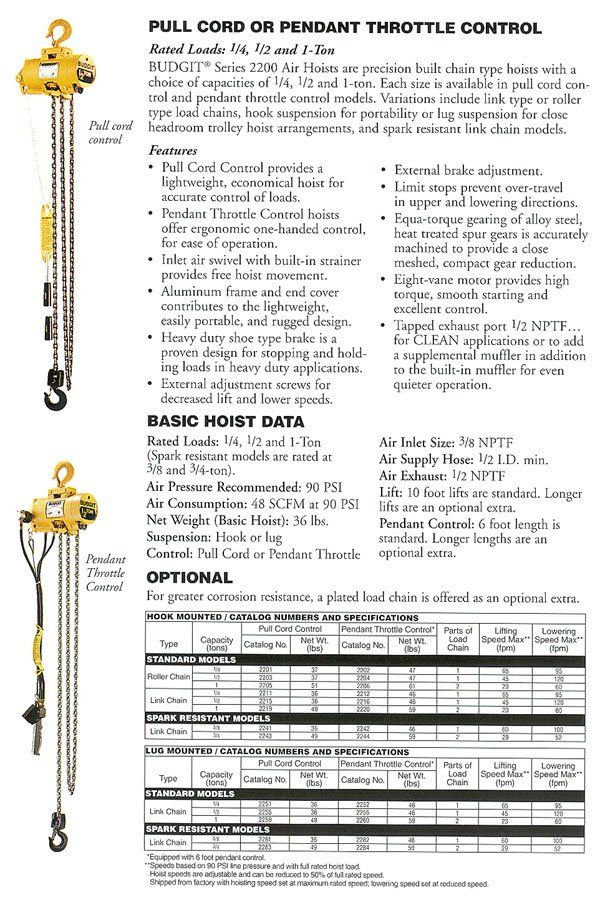

CM AirStar Air Hoist

Designed for general commercial applications where variable speed pneumatic power is preferable. Rated for 1/4, 1/2 and 1 ton capacities, this compact, lightweight hoist features:

- Hoistaloy load chain for heavy duty or stainless steel chain for spark resistant, medium duty loads

- Positive action, heavy-duty shoe type brake that holds the load

- Multi-vane rotary air motor for high torque, smooth operation

- Accurately machined heat treated alloy steel spur gears

- Spark resistant models available for hazardous environments

- Pull cord or pendant throttle control available

- Pull cord control hoists provide a lightweight, economical hoist for accurate control of loads

- Made in U.S.A.

CM Lodestar Air XL Pneumatic Chain Hoist

- Lifting capacities up to 7 1/2 tons

- Variable lifting speeds

- Maximum lifting speed of 31 feet per minute

- Forged ten-pocket oblique-lay liftwheel for smooth chain operation, constant chain speed and reduced chain wear

- Standard overload protector

- Clutch acts as upper and lower limits

- Six-Vane rotary air motor

- Pendant controls provide precise load spotting

- Air actuated motor brake for positive load control

- Factory tested at 125% of rated capacity

- Spark resistant models available

- Lifetime warranty

- Made in U.S.A.

CM Lodestar Electric Chain Hoist and Trolleys

The balanced, integrated, proven design of the Lodestar has made it the most popular electric chain hoist in the industry. Lodestar gives you more value for your money including:

- Up to 3 ton capacities for heavy-duty industrial applications

- Gear train lifetime lubricated with non-oxidizing grease

- Precision machined and hardened liftwheel with hardened chain guides for precise chain liftwheel fit

- Gearing designed for exceptionally long life and quiet operation

- H4 duty standard

- Rugged control station (NEMA 4)

- Hoist duty motor, standard Protector overload device and standard screw type limit switches

- Made in U.S.A.

CM Lodestar XL Electric Chain Hoists

- Lifting capacities from 2 to 7.5 tons

- Maximum lifting speed of 30 feet per minute

- Thermally protected motor

- Standard overload protector

- Heavy-duty, multiple disc braking system

- Gearing operated in oil bath

CM Powerstar Electric Chain Hoist and Trolleys

Designed specifically as an alternative to wire rope hoists for high speed lifting of loads from 2 to 20 tons in a space saving chain hoist. Features:

- H-4 or better rated duty cycle

- Designed for heavy-duty industrial applications from 2 to 20 ton capacities

- Liftwheel has machined chain pockets and is heat treated alloy steel for maximum strength and wear resistance

- Efficient regenerative braking system avoids heat generation in power train

- Heavy-duty multiple disc D.C. brake (dual braking system)

- Standard overload Protector device

- Lifetime warranty

- Made in U.S.A.

- 2 thru 20 ton capacities available

CM ShopAir

The CM ShopAir heavy-duty air chain hoist can be used as a

work station hoist or as a production line hoist. Lightweight, rugged

and compact design - for ease of portability - makes this hoist perfect for most air hoist lifting applications.

- CAPACITIES: 250 - 1,000 lbs.

- SPEEDS: up to 31 ft./min.

- AIR PRESSURE: Normal operating pressure is 90 PSI (capacities based on 80 PSI)

- Standard Protector overload device.

- Variable flow, two lever pendant for precise load spotting.

- Threaded external exhaust for piping away exhaust in clean room or painting applications.

- Small, compact design for commercial & industrial applications.

- Gear train is lifetime - lubricated with non-oxidizing grease.

- Lifetime warranty against defects in materials and workmanship.

- Made in USA.

CM ShopStar Electric Chain Hoist

- The ShopStar portable electric chain hoist features rugged construction and high H4 duty cycle. It keeps lifting and lifting, up to 1,000 pounds and 300 motor starts per hour.

- 10 pocket oblique lay liftwheel provides longer chain wear

- NEMA 4 industrial rated control station

- Gear train lifetime lubricated with non-oxidizing grease

- CM Hoist Alloy Load Chain

- Dual braking system - D.C. plus regenerative

CM Valustar Electric Chain Hoist

Designed specifically for general commercial applications. This compact, lightweight hoist features:

- Fully machined and heat treated liftwheel with hardened chain guides for smooth chain operation and reduced chain wear

- Standard lift 10, 15 & 20 ft.

- 5 ft. power cord length

- Heavy-duty caliper type AC brake

- Rugged NEMA 4 control station, 115 volt control circuit

- Easy to install and maintain

- Hoistaloy load chain for smooth operation and maximum chain life

- Efficient regenerative braking system to avoid heat generation in power train

- Made in U.S.A.

CM Air Manipulator Hoist

The CM TMM-140 is ideal for workstation applications. Lightweight and portable, the unit weighs less than 20 pounds and operates at 100% (A5) duty cycle.

- Smooth operator - Efficient rotary vane motor provides high uniform torque for quick response, and smooth, quiet operation.

- Easy to use - Handle-mounted pendant control for one-handed operation and load positioning.

- Variable speeds - Precise and infinite speed control for accurate load spotting.

- Wire rope design - Self-winding lifting cable stores conveniently inside unit.

- Suspension - Swivel top and bottom hooks with hook latches standard, for portability and quick installation.

- Disc brake - Secures load and eliminates drift when pendant is released.

CM Apollo Wire Rope Hoists and Trolleys

The Apollo compact wire rope hoist provides high hook lift with no design compromises. It lets you choose from the widest range of lifts, lifting speeds, clearances, mounting options and controls of any hoist on the market. It features:

- Weston-type mechanical load brake and multiple disc motor brake

- 2-20 ton capacity for wide range of lifting needs

- Low headroom design

- Double reduction reduced gearing provides smooth, quiet drive train

- NEMA 4, 4x/12 enclosed push-button control

- Made in U.S.A

CM Polaris Wire Rope Hoists and Trolleys

Rugged wire rope hoist with lift capacity up to five tons features:

- Motor mounted disc brake

- Hoist duty motor drive and gear train arrangement

- Frame = welded steel, (2 sizes - short and long)

- Brakes - multiple disc D.C. motor brake, and Weston style mechanical

- Alloy aluminum gear case and cover

- Made in U.S.A.

Please contact Milwaukee Crane's expert staff for applications assistance for CM Hoist products.

- Shaw Box

Shaw Box Hoists

Shaw Box versatile high-performance wire rope hoists

Shaw-Box wire rope hoists are ideally suited for virtually any lifting application. These modular, versatile hoists offer capacities from 1/2 to 100 tons, lifts from 12 to 259 feet, hoisting speeds from 8 to 56 feet per minute, and many control options. Components are available to build a wide variety of overhead cranes from 1/2 to 100 ton capacity, spans to 120 feet. Electric or air-powered, indoor or outdoor duty, general or severe industrial service, for standard, corrosive or explosive environments Shaw-Box has the products to fit your overhead material handling requirements.

Shaw Box World Series Wire Rope Hoist

- 5, 7 1/2 & 10 ton models

- Metric capacity rated

- Low headroom design for maximum lift

- Designed for H4 service minimum

- Electrics to N.E.C. standards

- 2-speed hoists & trolleys

- NEMA 4/12 panel

- 6:1 ratio on hoist, 3:1 on trolley, high to low speeds

- Upper / lower geared limit switch

- Upper block operated limit switch

- Runs on beam flanges 4 5/8”- 20” wide; on beams to 2” thick

- Hoist gearing in separate, easily accessible gear case

World Series Hoist catalog in PDF (400 KB)

World Series Trolley catalog in PDF (652 KB)

Shaw Box Wire Rope Hoists

- 1/2 to 25 ton capacity

- Electric

- Air Operated

- Low Headroom

- Spark Resistant

- Explosion Proof

Shaw Box Hoist catalog in PDF (1314 KB)

Top- Running Trolleys

- 5 to 100 ton capacity

- Electric

- Air Operated

- Spark Resistant

- Explosion Proof

Shaw Box TR Trolley catalog in PDF (567 KB)

Crane Components

- Top-Running

- Under-Running

- Single Girder

- Double Girder

- Electric

- Air Operated

- Spark Resistant

- Explosion Proof

Shaw Box catalog in PDF (1011 KB)

Please contact Milwaukee Crane for assistance with your Shaw Box questions and applications.

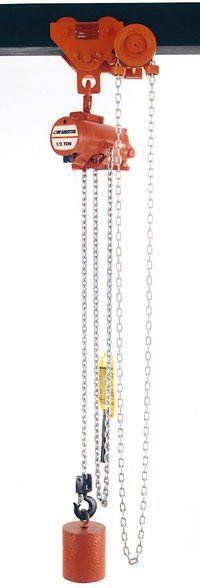

- R & M Hoists

R&M Hoists

Spacemaster SX and Spacemaster EX Explosion Proof

R&M SPACEMASTER� SX WIRE ROPE HOIST

The R&M Spacemaster� SX represents a revolutionary new generation of exceptionally reliable electric wire rope hoists, featuring advanced technology and cutting-edge performance.

An innovative design that includes a large drum diameter gives Spacemaster� SX wire rope hoists the lowest headrooms and best wheel loads in the industry, while providing near true vertical lift with single reeved hoists, and both exceptional hook approaches and heights of lift. Unique features included new low maintenance, sealed brakes; a two-speed hoist motor; and trolley inverter control. A NEMA 4 type control enclosure is also standard. Spacemaster� SX wire rope hoists are designed to meet and exceed either ASME H3 or ASME H4 duty (FEM 1Am, 2m, or 3m) ratings and provide the ultimate in easy load handling, safe operation and lasting, trouble-free performance.

Standard configurations include normal headroom, low headroom and double girder trolley designs. Wire rope hoists in short ton ratings (ASME) or metric ratings (FEM) meet a wide variety of application requirements:

- 1/2 - 75 ton (500 - 75,000 kg) capacities

- Lifts starting at 13ft (4m) to 320ft (100m) and beyond

- Lift speeds 10/1.5 - 62/10 fpm (3/0.5 - 19/3 m/min)

- 208, 230, 460, 575/3/60 or 380/3/50 supply

- Single reeved or double reeved

EASE OF OPERATION

Large-diameter hoist drum means easy positioning, closer approaches.

The larger rope drum diameter provides nearly true vertical lift with a single reeved hoist — only 1/8" drift per foot of lift. The result is exceptionally smooth movement and fast load positioning. This innovative design also means a shorter frame length, allowing closer end approaches.

Hoist and trolley motors designed for space savings and productivity.

Standard two-speed hoist motor (6:1 ratio), designed specifically for hoisting applications, offers high starting torque and ensures precise and reliable load handling.

This motor is class F insulated, 30 minute rated (60% effective duty), thermally protected and totally enclosed.

The trolley motor's standard inverter control offers two-step or infinitely variable speed control for smooth acceleration and deceleration; minimal load swing; fast, efficient handling; and accurate load placement.

R&M SPACEMASTER� EX HAZARDOUS LOCATION WIRE ROPE HOIST

The Spacemaster EX is the hazardous location version of the industry leading Spacemaster SX hoist. An innovative design that includes a large drum diameter gives the Spacemaster EX hoists the lowest headrooms and best wheel loads in the industry, while providing near true vertical lift with single reeving, as well as exceptional hook approaches and heights of lift.

STANDARD CONFIGURATION

- Foot mount, low headroom, normal headroom and double girder

- 1-1/2—20 ton [1600—20,000 kg] capacities

- Lifts starting at 13ft [4m] to 324ft [99m] and beyond

- Lift speeds 10/1.5—62/10 fpm [3/0.5—19/3 m/min.]

- 460, 575/3/60 or 380/3/50 supply

- ASME H3 or ASME H4 duty [FEM 1Am, 2m, or 3m] ratings

- For Class I group C & D Division 2 Applications

- Temperature classification is T3

- Single reeved or double reeved

STANDARD FEATURES

- Two speed hoist with 6:1 ratio, contactor control

- Hoist motor is class F insulated, 60% effective duty and thermally protected

- Low maintenance, sealed hoist brake

- Two speed trolley with 4:1 ratio, contactor control

- Electro-mechanical load limit switch

- 2-position hoist limit switch

- IP55/NEMA 4 rated control panel

- CSA C/US approved

- Approx. 40:1 drum to rope diameter ratio for extended rope life

- Rope guide with spring loaded pressure roller

- Trolley motor with compact disc brake

- Trolley bumpers

- Mainline contactor

- 115 Volt control transformer

- Push-button assembly & pendant

- Available options: bronze coated load hook; bronze trolley wheels

Please contact Milwaukee Crane's expert staff for applications assistance for R&M Hoist products.

- Harrington Hoists

Harrington Hoist

High Duty Cycle Chain Hoists to 20 Tons Capacity

Harrington Hoist

NER/ER SINGLE SPEED HOOK SUSPENSION

- Standard length of power supply cable is 15'. For more information on power supply system, contact the Harrington distributor nearest you.

- Special lengths of load chain, push-button cord or power supply cables are available upon request.

- Harrington load chain is case-hardened Grade 80 chain.

- Optional canvas chain containers are available.

- Optional steel chain containers are available if lifting height exceeds limit of canvas chain container.

- Lug mount available

Harrington Hoists

NERM/ERM SINGLE SPEED WITH SINGLE SPEED TROLLEY

- Brakes on trolley motors are standard.

- Standard length of power supply cable is 30'. For more information on power supply system, contact the Harrington distributor nearest you.

- Special lengths of load chain, push-button cord, or power supply cable are available upon request.

- Harrington load chain is case-hardened Grade 80 chain.

- Optional steel chain containers are available if lifting height exceeds limit of canvas chain container.

- Push button switches come in a standard 4-button type (Up/Down, Traverse) for monorails.

- Additional control features available.

- Shown with optional canvas chain container.

Harrington Hoist

NERG/ERG SINGLE SPEED WITH GEARED TROLLEY

- Standard length of power supply cable is 15'. For more information, contact the Harrington distributor nearest you.

- Special lengths of load chain, push-button cord or power supply cables are available upon request.

- Harrington load chain is case-hardened Grade 80 chain.

- Optional steel chain containers are available if lifting height exceeds limit of canvas chain container.

- Push button switches come in a standard 2-button type (Up/Down) for monorails.

- Additional control features available.

- Show with optional canvas chain container.

Harrington Hoists

NERP/ERP SINGLE SPEED WITH PUSH TROLLEY

- Standard length of power supply cable is 15'. For more information, contact the Harrington distributor nearest you.

- Special lengths of load chain, push-button cord or power supply cables are available upon request.

- Harrington load chain is case-hardened Grade 80 chain.

- Optional steel chain containers are available if lifting height exceeds limit of canvas chain container.

- Push button switches come in a standard 2-button type (Up/Down) for monorails.

- Additional control features available.

Harrington Hoist

NER/ER DUAL SPEED HOOK SUSPENSION

- Standard length of power supply cable is 15'. For more information on power supply system, contact the Harrington distributor nearest you.

- Special lengths of load chain, push-button cord or power supply cables are available upon request.

- Harrington load chain is case-hardened Grade 80 chain.

- Optional steel chain containers are available if lifting height exceeds limit of canvas chain container.

- Shown with optional canvas chain container.

- Lug mount available

Harrington Hoists

NERM/ERM DUAL SPEED WITH SINGLE SPEED MOTORIZED TROLLEY

- Brakes on trolley motors are standard.

- Standard length of power supply cable is 30'. For more information on power supply system, contact the Harrington distributor nearest you.

- Special lengths of load chain, push-button cord or power supply cables are available upon request.

- Harrington load chain is case-hardened Grade 80 chain.

- Optional steel chain containers are available if lifting height exceeds limit of canvas chain container.

- Push button switches come in a standard 4-button type (Up, Down, Traverse) for monorails.

- Additional control features available.

Harrington Hoist

NERM/ERM DUAL SPEED WITH DUAL SPEED MOTORIZED TROLLEY

- Brakes on trolley motors are standard.

- Standard length of power supply cable is 30'. For more information on power supply system, contact the Harrington distributor nearest you.

- Special lengths of load chain, push-button cord or power supply cables are available upon request.

- Harrington load chain is case-hardened Grade 80 chain.

- Optional steel chain containers are available if lifting height exceeds limit of canvas chain container.

- \Push button switches come in a standard 4-button type (Up/Down,Traverse) for monorails.

- Additional control features available.

- Optional canvas chain container shown.

Harrington Hoist

ERM LARGE CAPACITY 8T THROUGH 20T MOTORIZED TROLLEY

- Brakes on trolley motors are standard.

- Standard length of power supply cable is 30'. For more information on power supply system, contact the Harrington distributor nearest you.

- Special lengths of load chain, push-button cord or power supply cables are available upon request.

- Harrington load chain is case-hardened Grade 80 chain.

- Optional steel chain containers are available if lifting height exceeds limit of canvas chain container.

- Push button switches come in a standard 4-button type (Up/Down, Traverse) for monorails.

- Additional control features available.

There are many other Harrington Hoist models and options available. Please contact Milwaukee Crane's expert staff for applications assistance for Harrington Hoist products.

- P & H New Crane & Hoist Parts

P&H Crane Replacement Parts

P & H Crane Parts from Milwaukee Crane

Milwaukee Crane has one of the largest stocks of P&H crane parts anywhere.

- Immediate delivery from stock on most P&H parts

- We ship P&H parts worldwide.

Genuine P&H Crane Parts Available

P & H Parts Available for Immediate Delivery

Milwaukee Crane stocks genuine P&H crane replacement parts. We have P & H replacement parts and components for most P & H cranes. We are authorized distributors for P&H Cranes, Hoists and parts!

We ship P&H parts worldwide.

Note: We do sell parts for P & H mobile cranes. Please inquire.

Don't see the P & H part you need?Please contact us for assistance.

| Genuine P&H Parts Available |

||

|

1007Z375 |

SAFETY LATCH |

|

|

100E1076-1 |

MAGNET ASSEMBLY |

|

|

100E2397-2 |

PUSH BUTTON |

1 SPEED |

|

100E2504-1 |

SWITCH ASSEMBLY |

|

|

100E2783-4 |

INTERLOCK |

|

|

100E2783-6 |

INTERLOCK |

|

|

100E4438-1 |

SWITCH |

|

|

100E4537-2 |

PUSH BUTTON |

5 SPEED |

|

100E4538-2 |

PUSH BUTTON |

2 SPEED |

|

100E4966-3 |

BRAKE RECTIFIER |

|

|

100E6558-1 |

INTERLOCK |

|

|

100E695-7 |

LIMIT SWITCH ASSEMBLY |

|

|

100F682-2 |

SWITCH |

|

|

1014Z2805 |

COVER |

|

|

1014Z3145 |

GEAR CASE ASSEMBLY |

|

|

1016Z948 |

HANGER ANCHOR |

|

|

1017Z1 |

SPRING |

|

|

1018Z6333 |

SNAP RING |

|

|

1010Z11231 |

ROD END |

|

|

1045Z666 |

BRAKE REPAIR KIT |

|

|

1045Z87 |

SPRING W/ CASE |

|

|

1048Z22 |

SEAT CUSHION |

|

|

1075Z1611 |

TRANSISTOR MODULE |

|

|

1079Z1215 |

CONTACT KIT |

|

|

1079Z1217 |

CONTACT |

|

|

1079Z213 |

TIP |

|

|

1079Z2159 |

CONTACT |

|

|

1079Z4511 |

CONTACT KIT |

|

|

1079Z4512 |

CONTACT KIT |

|

|

1079Z4513 |

CONTACT KIT |

SIZE 1-3/4 |

|

1079Z4519 |

CONTACT KIT |

|

|

1079Z4522 |

CONTACT KIT |

SIZE 2 |

|

1079Z4524 |

CONTACT KIT |

|

|

1079Z4550 |

MOVABLE CONTACT |

|

|

1079Z4551 |

STATIONARY CONTACT |

|

|

1079Z4552 |

STATIONARY CONTACT |

|

|

1079Z606 |

CONTACT |

|

|

10F9079D1 |

SHAFT |

13" SBE |

|

10F9105D5 |

SHAFT |

|

|

1100F2-2 |

SHAFT / FLANGE KIT |

|

|

100H37-1 |

REPAIR KIT FOR 100J4109-1 HYDRAULIC CYLINDER |

|

|

1100T179-1 |

SEAL REPAIR KIT |

|

|

110E81F7 |

CONTACT BLOCK |

|

|

13F1879D1 |

BRAKE WHEEL |

10" |

|

13Z333 |

WHEEL |

|

|

13Z403 |

ROLLER |

|

|

14H493 |

WASHER |

|

|

14Q94 |

JUNCTION BOX |

|

|

15F388 |

ROD |

|

|

15F391C2 |

LINING |

|

|

15F427 |

DISC PLATE |

|

|

15F486 |

PIVOT LINK |

|

|

15F518 |

DISC |

|

|

15Q6 |

DISC |

|

|

15Q87D1 |

FRICTION DISC |

|

|

15Q91D1 |

BRAKE DISC |

|

|

15Q93D1 |

FRICTION DISC |

|

|

15U78D2 |

BRAKE |

|

|

16Z119 |

SUPPORT |

|

|

16Z509D1 |

BUMPER |

|

|

17H124 |

SPRING |

|

|

17H126 |

SPRING |

|

|

17H128 |

SPRING |

|

|

17H218 |

SPRING |

|

|

17H281 |

SPRING |

|

|

17H317 |

SPRING |

|

|

17H327 |

SPRING |

|

|

17H401 |

SPRING |

|

|

17H451 |

SPRING |

|

|

17Q22 |

SPRING |

|

|

17Z103 |

SPRING |

|

|

17Z140 |

SPRING |

|

|

17Z147 |

SPRING |

|

|

17Z161D1 |

SPRING |

|

|

17Z165 |

SPRING |

|

|

17Z174 |

SPRING |

|

|

17Z183 |

SPRING |

|

|

17Z222 |

SPRING |

|

|

17Z286D13 |

SPRING WASHER |

|

|

17Z286D14 |

WASHER |

|

|

17Z286D15 |

SPRING WASHER |

|

|

17Z286D17 |

WASHER |

|

|

17Z286D20 |

SPRING WASHER |

|

|

17Z286D46 |

WASHER |

|

|

17Z294 |

SPRING |

|

|

17Z397 |

SPRING |

|

|

17Z403 |

SPRING |

|

|

17Z548D1 |

SPRING W/ PLATE |

|

|

17Z548D2 |

SPRING W/ PLATE |

|

|

17Z548D3 |

SPRING W/ PLATE |

|

|

17Z548D5 |

SPRING W/ PLATE |

|

|

17Z652 |

SPRING |

|

|

17Z760 |

SPRING |

|

|

17Z797 |

SPRING |

|

|

17Z888 |

COMPRESSION SPRING |

|

|

17Z942 |

SPRING |

|

|

17Z944 |

SPRING |

|

|

18F1825 |

SPACER |

|

|

18F1866D1 |

SPACER |

16" SBE BRAKE |

|

18F1866D2 |

SPACER |

|

|

18F1866D3 |

SPACER ARMATURE |

19" SBE BRAKE |

|

20F315 |

BRAKE ROD |

|

|

20H4195 |

BRAKE STUD |

|

|

278F1559D1 |

SHOE |

|

|

301F1037F2 |

SHAFT |

D FRAME |

|

301F1068C1 |

PINION |

|

|

301F1069C1 |

PINION |

|

|

301F1233 |

PINON GEAR |

|

|

301F1375 |

PINION |

|

|

301F1423 |

PINION GEAR |

|

|

301F1448 |

PINION |

|

|

301F1527F1 |

SHAFT |

|

|

301F298F1 |

PINION ASSEMBLY |

|

|

301F288F1 |

PINION ASSEMBLY |

|

|

301F829 |

GEAR |

|

|

301F888D2C1 |

DRUM GEAR |

|

|

301F889F2 |

SHAFT |

|

|

301H569 |

GEAR |

|

|

301H588 |

INTERMEDIATE PINION |

|

|

301H595 |

PINION |

|

|

307F228C1 |

SHEAVE |

|

|

307F229C1 |

SHEAVE |

|

|

307F236 |

SHEAVE |

|

|

307F91 |

SHEAVE |

|

|

307H54C1 |

SHEAVE |

|

|

301F1124F1 |

HOOK |

|

|

308F1127F1 |

HOOK ASSEMBLY |

|

|

308F1136F0 |

HOOK ASSEMBLY |

|

|

308F1144 |

HOOK |

|

|

308F564 |

HOOK |

|

|

308F724F1 |

HOOK |

|

|

308F868F1 |

HOOK ASSEMBLY |

|

|

30Z120F1 |

CABLE ASSEMBLY |

|

|

30Z120F2 |

CABLE |

|

|

30Z120F4 |

CABLE |

|

|

30Z121F2 |

CABLE ASSEMBLY |

|

|

30Z140F2 |

CABLE |

|

|

3100E771-1 |

BRAKE |

|

|

3100F686-8 |

GEAR CASE |

|

|

310H277F1 |

SHAFT ASSEMBLY |

|

|

310H508F1 |

SHAFT |

|

|

313F1151 |

RATCHET ASSEMBLY |

|

|

313F1161 |

RATCHET ASSEMBLY |

|

|

313F352 |

HUB |

|

|

313F488 |

HUB |

|

|

313F596 |

HUB |

|

|

313F665 |

HUB |

|

|

313F799 |

HUB |

|

|

313F907 |

TRUCK WHEEL IDLER |

|

|

314A141 |

GEAR CASE |

|

|

314F356 |

COVER |

|

|

314F626 |

COVER |

|

|

315F133 |

PLATE |

|

|

315F134 |

PLATE |

|

|

315F136 |

PLATE |

|

|

315F138 |

PLATE |

|

|

315F140 |

DISC PLATE |

|

|

315F193 |

DISC |

|

|

315F196 |

FRICTION DISC |

|

|

315F198 |

FRICTION DISC |

|

|

315F200 |

FRICTION DISC |

|

|

315F27D2 |

DISC PLATE |

|

|

315F74C2 |

DISC |

|

|

318F1897F2 |

COUPLING |

|

|

318F1898F2 |

COUPLING |

|

|

318F1900F2 |

COUPLING |

|

|

318F1901F2 |

COUPLING |

|

|

318H1880C1 |

COUPLING |

|

|

318H1900C1 |

COUPLING |

|

|

318H1909C1 |

COUPLING |

|

|

318H1925C1 |

COUPLING |

|

|

318H1926C1F1 |

COUPLING |

|

|

318H1964 |

DRUM SLEAVE |

|

|

318H2000 |

DRUM SLEAVE |

|

|

318H2040 |

DRUM SLEAVE |

|

|

6100E429F1 |

BOTTOM BLOCK ASSEMBLY |

|

|

6988E401-5 |

MOTOR |

|

|

73Q5 |

BRUSH HOLDER |

|

|

73Q6 |

BRUSH HOLDER |

|

|

73Q7 |

BRUSH HOLDER |

|

|

73Q8 |

BRUSH HOLDER |

|

|

75Q336D1 |

TRANSFORMER |

|

|

75Z1091D1 |

RECTIFIER |

|

|

75Z23D1 |

TRANSFORMER |

|

|

75Z331D1 |

RECTIFIER |

|

|

75Z456D3 |

RECTIFIER |

|

|

75Z514D1 |

TRANSFORMER |

|

|

75Z578D1 |

RECTIFIER |

|

|

75Z578D4 |

RECTIFIER |

|

|

75Z57D1 |

TRANSFORMER |

|

|

75Z590D13 |

DIODE |

|

|

78F247F1 |

WHEEL |

|

|

78F294 |

SHOE |

|

|

78H237 |

INSULATOR |

|

|

78H243 |

BRACKET |

|

|

79F1435C1 |

SHIELD |

|

|

79H1042C1 |

ARC SHIELD |

|

|

79H1043C1 |

ARC SHIELD |

|

|

79H1125 |

CONTACT |

|

|

79H1356 |

CONTACT SUPPORT |

|

|

79H1456D1 |

CONTACT STATIONARY |

|

|

79H1457D1 |

CONTACT |

|

|

79H1458 |

INSULATOR |

|

|

79H1586D2 |

CONTACT |

|

|

79H1606 |

CONTACT |

|

|

79H1607 |

CONTACT |

|

|

79H1683 |

TIP |

|

|

79H1684 |

TIP |

|

|

79H1833 |

TERMINAL BAR |

|

|

79H1922 |

CONTACT |

|

|

79H2017C1 |

SWITCH |

|

|

79H2171 |

TIP |

|

|

79H2181 |

TIP |

|

|

79H583 |

INSULATOR |

|

|

79H618 |

BAR |

|

|

79H734 |

CONTACT TIP |

|

|

79Q1050D5 |

CONTACT BLOCK |

|

|

79Q1050D7 |

CONTACT BLOCK |

|

|

79Q1051D3 |

RELAY |

|

|

79Q1052D1 |

CONTACTOR |

|

|

79Q1056D1 |

RELAY |

|

|

79Q1057D4 |

CONTACTOR |

|

|

79Q638 |

CONTACTOR |

|

|

79R453D501 |

FUSE |

|

|

79U10D2 |

MODULE |

|

|

79U2485D1 |

BRAKING MODULE |

|

|

79U2488D2 |

INTERFACE BOARD |

|

|

79U6D3 |

MODULE |

|

|

79Z1738D2 |

CABLE GUIDE |

|

|

79Z2475D1 |

NETWORK |

|

|

79Z264D20 |

TIMER |

|

|

79Z3145 |

CONTACT TIP |

|

|

79Z3253D2 |

RELAY |

|

|

79Z3293 |

LIMIT SWITCH |

|

|

79Z602D1 |

HOOD, BLACK |

|

|

79Z602D2 |

HOOD, GREEN |

|

|

79Z602D3 |

HOOD, RED |

|

|

79Z602D4 |

HOOD, ORANGE |

|

|

79Z602D5 |

HOOD, YELLOW |

|

|

79Z602D2 |

HOOD, BLUE |

|

|

79Z95D5 |

FUSE |

|

|

79Z994D4 |

RELAY |

|

|

80F386D4 |

SEGMENT |

|

|

80F387D13 |

SEGMENT |

|

|

80F387D14 |

SEGMENT |

|

|

80F387D2 |

SEGMENT |

|

|

80F387D3 |

SEGMENT |

|

|

80F387D4 |

SEGMENT |

|

|

80H679 |

|

|

|

80H681 |

CAM |

|

|

80H682 |

CAM |

|

|

80H684 |

CAM |

|

|

80H961 |

CONTACT |

|

|

80Q35D5 |

VARISTOR |

|

|

80Z117 |

SCREW |

|

|

815E1601 |

ARMATURE PLATE |

|

|

815E1608 |

DISC |

|

|

818H1447 |

BUSHING |

|

|

819H67D37 |

DRIVE LOCK PIN |

|

|

81A55 |

ARMATURE |

|

|

81 E44 |

ARMATURE |

|

|

81E83D1 |

ARMATURE PLATE |

|

|

81F82C1 |

ARMATURE |

|

|

81H109 |

CLAMP |

|

|

81H115 |

CLAMP |

|

|

81H13 |

CLAMP |

|

|

81H50 |

CLAMP |

|

|

81H59 |

CLAMP |

|

|

820F1517 |

BRAKE STUD |

|

|

820H1601D1 |

GASKET |

|

|

85Z24D8 |

CORD GRIP |

|

|

87H43 |

COVER |

|

|

87Z23 |

RECEPTACLE |

|

|

88Z390D10 |

MOTOR |

|

|

8Z388D3 |

LATCH KIT |

|

|

8Z388D5 |

LATCH KIT |

|

|

8Z388D6 |

LATCH KIT |

|

|

8Z64D17 |

LATCH KIT |

|

|

8Z64D21 |

LATCH KIT |

|

|

8Z64D25 |

LATCH KIT |

|

|

8Z64D27 |

SAFETY LATCH |

|

|

8Z64D3 |

LATCH KIT |

|

|

8Z64 D7 |

LATCH KIT |

|

|

8Z64D9 |

LATCH KIT |

|

|

9085-1 |

SHUNT |

|

|

914F85-3 |

TOP COVER ASSEMBLY 6 HOLE P.B. |

|

|

914F85-4 |

FRONT COVER 8 HOLE P.B. |

|

|

914F86-4 |

BACK COVER 8 HOLE P.B. |

|

|

915F71-1 |

BRAKE SHOE |

|

|

915F73-1 |

BRAKE SHOE |

|

|

915F84-1 |

BRAKE SHOE |

|

|

915F84-4 |

BRAKE SHOE |

|

|

9308F115-28 |

CABLE |

|

|

9308F32-33 |

CABLE |

|

|

9308F41-1 |

CABLE |

|

|

9308H112-1 |

CABLE |

|

|

9308H112-2 |

CABLE |

|

|

9308H129-1 |

CABLE |

|

|

9308H129-2 |

CABLE |

|

|

9308H168-1 |

CABLE |

|

|

9308H174-1 |

CABLE |

|

|

9308H48-5 |

CABLE |

|

|

9310F102-4 |

DRUM PINION LEFT HAND |

|

|

9310F122-4 |

DRUM PINION LEFT HAND |

|

|

9310F123 |

DRUM PINION |

|

|

9318H31-1 |

SPRING |

|

|

9318HH31-2 |

SPRING |

|

|

9318H31-4 |

SPRING |

|

|

9325H48-1 |

BEARING ASSEMBLY |

|

|

9398-1 |

SUPPORT |

|

|

9601E410F1 |

LIMIT SWITCH ASSEMBLY |

|

|

9601E410F2 |

SWITCH DRIVE SHAFT ASSEMBLY |

|

|

9679F401-1 |

LIMIT SWITCH ASSEMBLY |

|

|

9681E402F1 |

BRAKE SOLENOID & PLATE |

|

|

973F83-1 |

BRUSH HOLDER ASSEMBLY |

|

|

973F91-3 |

BRUSH HOLDER ASSEMBLY |

|

|

975E47-12 |

POT ASSEMBLY |

|

|

975E632-2 |

COIL |

|

|

979E269-1 |

ARC SHIELD |

|

|

979H101-1 |

CONTACT |

|

|

979H99-1 |

CONTACT |

|

|

981A6-4 |

POT ASSEMBLY |

|

|

981A7-4 |

POT ASSEMBLY |

|

|

981E48-2 |

POT ASSEMBLY |

|

|

9314E91-1 |

GEAR CASE COVER |

E FRAME |

|

9314E98-1 |

GEAR CASE COVER |

D FRAME |

|

981A5-10 |

MAGNETIC POT ASSEMBLY 100 VOLT |

CD-5 |

|

981A5-2 |

MAGNETIC POT ASSEMBLY 18 VOLT |

CD-5 |

|

F386D3 |

SEGMENT |

|

|

F387D4 |

SEGMENT |

|

|

R24286 D1 |

BRAKE DISC |

HEVI-LIFT HOIST |

|

R24288 D1 |

BRAKE DISC |

HEVI-LIFT HOIST |

|

SURPLUS MOTORS |

||

|

MOTOR |

7-1/2 HP 1145 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 324 FRAME TENV |

|

|

MOTOR |

10 HP P&H 1750 RPM SINGLE SPEED HOIST MOTOR 230/460 VOLT FRAME S250 UY TYPE SCTA SINGLE BEARING W/ SPLINED OUT PUT SHAFT FLANGE MOUNT TO FIT HEVI-LIFT HOIST |

|

|

MOTOR |

20 HP 1145 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 326X FRAME TENV |

|

| MOTOR |

25 TON 1710 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 324 ROUND FRAME SINGLE BEARING W/ SPLINED OUTPUT SHAFT FLANGE MOUNT TO FIT HEVI-LIFT HOIST |

|

| MOTOR | 40 HP 1750 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 365X FRAME TENV | |

| MOTOR | 25 HP 1710 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 324 FRAME TENV | |

| MOTOR | 60 HP 1130 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 365 XL | |

| MOTOR | 75 HP 1150 RPM P&H WOUND ROTOR MOTOR 230/460 VOLT HEW 444 X TENV | |

- Ace Worldwide

Ace Heavy Duty Hoists

Standard or Custom Designed Wire Rope Hoists from Ace

Ace manufactures heavy duty wire rope hoists for a broad range of applications in any combination through 550 tons and CMMA Class F.

Special applications include:

Hazardous Locations

Hot Metal

Low Headroom

Polar Hoists

Twin Drum Bucket

Critical Lift Applications

Magnet Applications

Motorized Lifting Beams

Motorized Hook Blocks

Bucket Hoists

Twin Drum

Transfer Cars

Ace Hoist Design Features

Ace Hoist Limit Switches

Rotary geared control circuit, upper and lower limit switch, automatically de-energizing hoist drive at field set extremities of hook travel, plus a weight-operated control circuit upper limit switch.

Ace Hoist Motor

Foot-mounted, totally enclosed, 60-minute Class H minimum insulation. Directly connected to hoist reducer via gear coupling.

Ace Trolley Drive

Continuous duty, Class F motor with DC disc brake and helical gear reducer mounted on axle.

Ace Trolley Wheels

Precision, 1060 steel, double flange with hardened treads and flanges to 320 Brinell. Double spherical, roller-type bearings in modified MCB capsules.

Ace Drum

Fabricated steel all-welded construction, supported on anti-friction bearings and furnished complete with left and right hand grooving for a true vertical plumb hook lift

Ace Hoist Electric Brake

Foot-mounted, self aligning floating shoe, 150% minimum, torque-rated, shoe-type electric motor brake. Brake wheel is mounted on reducer input shaft.

Ace Trolley Frame

Fabricated steel, all-welded frame, precision bored to ensure consistent true tracking cross bridge operation. Heavy ribbed plate decking provides support of main Hoist-Trolley components. Upper sheave nest is serviceable from top side of main machinery deck. Rubber bumpers included on all four corners of trolley.

Ace Hook Block

All fabricated, steel enclosed housing for maximum safety, with high carbon steel heat-treated 320 Brinell sheaves and roller bearings, forged steel hook with latch

Ace Hoist Gear Reducer

Fabricated steel, horizontally-split housing with through heat-treated (40-45 Rc) alloy steel gearing and roller type bearing mounted in cartridges. Weston type mechanical load brake up to 50 hp. Ace family of reducers vary from 30 to 1500 hp.

-

Button

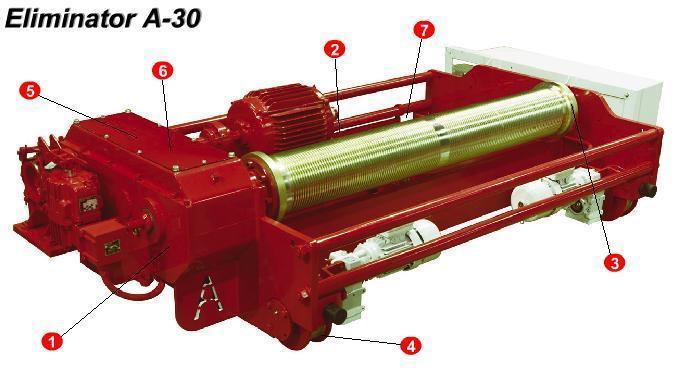

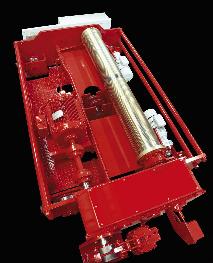

(1) As with all heavy-duty Ace World Companies hoists, The Eliminator class hoists have reducer cases that split along the center-line of the shafts to facilitate easy repair and reduced maintenance cost.

-

Button

(2) Sheaves are hardened to 400 Brinell for reduced maintenance and long life under the most demanding applications. Sheaves are easily accessible to reduce down time during wire rope inspection and replacement.

-

Button

(3) The drum tail bearing is an easily accessible, piloted flanged, spherical-roller bearing that is designed for long no-maintenance service. If replacement is required years down the road - it can be done quickly, easily, accurately and inexpensively.

-

Button

(4) Wheels are heat treated to 400 Brinell for durability and freedom from maintenance. Strong alloy steel shafts are supported on both ends by encapsulated, double-row, spherical-roller bearings with an L-10 life exceeding 10,000 hours.

-

Button

(5) Hoist gearing is helical with a 25 degree pressure angle for high strength. Gears are cut from through-hardened forgings and have a hardness of 40 to 42 Rockwell "C" scale for durability, long life and low maintenance.

-

Button

(6) The full length removable

inspection cover allows full visual inspection of all gears, shafts and bearings even with a load on the hook. If the unit is equipped with a mechanical load brake, it can be adjusted through the inspection opening without disassembling the reducer. This means inspections and adjustments are quick, easy and thorough.

-

Button

(7) Platforms provide safe easy access to all hoisting components for fast easy inspection, routine maintenance and rapid repair with minimum down time.

Cranes

- Milwaukee Crane

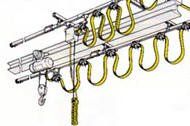

Electrification Products for Cranes

Milwaukee Crane has the right electrification product for you

Milwaukee Crane has world class crane and hoist electrification systems for new crane systems, crane rebuilds, crane retrofits and crane service.

The most frequently installed and serviced types of electrification are:

- Crane Bridge

- Cable Reel

- Shielded Bar

- Festoon Cable

- Monorail and Runway

- Cable Reel

- Shielded Bar

- Festoon Cable

Milwaukee Crane offers these fine product lines for your electrification needs:

- Duct-O-Wire

- Electromotive

- Insul-8

You can view detailed information at the above links.

Please contact Milwaukee Crane's expert staff for applications assistance with electrification products.

Milwaukee Crane Runway Systems

Runways for every crane application

Milwaukee Crane designs, fabricates and installs all standard types of crane runways as well as custom configurations:

Typical runway systems include:

- Top-Running Crane Runways

- Under-Running Crane Runways

- Patented Track Runways

- Enclosed Track Runways

All of the above runway systems can be installed in any of the following ways:

- Building Column Supported

- Floor Supported (tied back into building columns)

- Freestanding

- Ceiling Supported for light capacity ergonomic cranes

Contact Milwaukee Crane for assistance with your runway requirements.

- Gorbel Work Station Cranes

Enclosed Track Design

Gorbel Work Station Crane Systems utilize enclosed track that is high in strength and low in weight.

- Available in steel, stainless steel, and aluminum.

- Enclosed track cranes are up to three times easier to move than traditional bridge cranes.

- The design virtually eliminates dirt and dust from the rolling surface. This reduces wear on the wheels of the trolley and end trucks.

- The smooth running surface reduces rolling resistance.

- The low profile of the steel track allows the system to be installed where headroom is a problem.

- The low track weight reduces the applied forces exerted on the supporting structure. Long spans allow systems to be installed where hanging points are infrequent.

- Five capacities (250 lb., 500 lb., 1,000 lb., 2,000 lb., and 4,000 lb.) enable you to keep bridge weights and costs to a minimum.

The 2� taper of the running flange helps to center the trolley in the track for smooth, effortless movement of trolleys and end trucks.

Work Station Cranes Free Standing

Gorbel Free Standing Work Station Bridge Cranes can handle the toughest overhead lifting tasks. These cranes, which can be installed on any normal 6-inch reinforced concrete floor, feature a pre-engineered, modular design that can easily expand as your work centers expand.

- Available in steel, aluminum, and stainless steel.

- Range in capacities from 250 lb. to 4000 lb., with spans up to 30 feet.

- Easy to install, relocate, and expand.

- Provide ease of movement and positioning.

- Doesn't put stress on the building's overhead structure.

- Requires a reinforced concrete floor of at least 6 inches.

Work Station Cranes Ceiling Mounted

When a work area must be free from any support structures that may interfere with operations, ceiling mounted bridge cranes are an excellent solution to keeping floors clear. Handling capacities up to 4000 lbs. with overall bridge lengths up to 34 ft., these systems are pre-engineered and modularly designed for easy installation, expansion, and relocation. Customers can install multiple bridges along one set of runways and greatly increase their productivity.

- Available in steel, aluminum, and stainless steel.

- Capacities from 250 lb. to 4000 lb., with spans up to 30 feet.

- Easy to install, move, and position.

- Support steel doesn't interfere with the handling operation.

- Require buildings with adequate overhead structures.

Work Station Cranes Monorails

- Provide a solution for true linear movement.

- Pre-engineered modular designs enable Gorbel Work Station Crane Systems to be adapted for more sophisticated applications. This is done by the addition of extra tracks, curves, switches, and interlocks (transfers)

Monorail Curve

The monorail curve is a section of track that is formed to provide a 90� bend. Curve sections have a straight area that projects beyond the curve. The curve needs to be supported with three hangers.

Work Station Cranes Seismic Zone IV

Gorbel's Seismic Zone IV Cranes have been designed for the most rigorous applications in areas that must adhere to Seismic Zone IV building code requirements. These cranes are completely free standing and require no sway bracing. The pre-engineered modular kit design of Gorbel's Seismic Zone crane systems provide easy expansion or relocation.

- Designed for Seismic Zone IV.

- Capacities from 150 lb. to 4000 lb., with spans up to 30 feet.

- Easy movement for increased productivity.

- Steel and Aluminum enclosed track.

Workstation Jib Cranes Free Standing

Work Station Jib Cranes are the ideal substitute for traditional, heavy I-Beam Jib Cranes. These jibs are designed to service circular areas and support tool balancers, air balancers, vacuum lifters, and hoists. When floor mounted, they can accommodate up to a 360orotation. Capacities are available from 100 lbs. to 1000 lbs. with spans up to 16 feet.

- Capacities from 100 lb. to 1000 lb., with spans up to 16 ft.

- Offer 360� rotation.

- Most can be bolted directly to existing floor without adding special foundations.

- Utilize enclosed track for the boom assembly, which reduces dead weight for easier rotation than traditional I-beam jibs.

- Feature a retaining pin through the pivot pin to help resist accidental upward dislodgment of the boom assembly.

- Include hoist trolley.

- Roller bearings provide for unsurpassed ease of movement.

Workstation Jib Cranes Wall Cantilever

Work Station Jib Cranes are the ideal substitute for traditional, heavy I-Beam Jib Cranes. These jibs are designed to service circular areas and support tool balancers, air balancers, vacuum lifters, and hoists. When column or wall mounted, they can handle up to a 200orotation. Capacities are available from 100 lbs. to 1000 lbs. with spans up to 16 feet.

Capacities from 100 lb. to 1000 lb., with spans up to 16 ft.

- Available in steel (all capacities) or stainless steel (capacities to 500 lb.).

- Offer 200� rotation.

- Can be wall or column mounted.

- Utilize enclosed track for the boom assembly, which reduces dead weight for easier rotation than traditional I-beam jibs.

- Use tapered roller bearings at the pivot points for unsurpassed ease of rotation.

Workstation Jib Cranes Aluminum Tie Rod

The AL100 Wall Bracket Work Station Jib Crane utilizes Gorbel's patented light-weight, high strength extruded aluminum enclosed track. This revolutionary track reduces the rotational dead weight of the boom by 56% to 68%, making the jib up to 40% easier to rotate than comparable I-beam jibs. The tie rod design minimizes deflection and is more precise when positioning loads than other jibs.

- Wall mounted or column mounted

- Available in capacites from 150-2000 lbs. and spans up to 20 feet. (not available for 2000 lbs.)

- Utilizes Gorbel's patented light weight, high-strength extruded enclosed track on the boom.

- Weighs up to 355 lbs.

- Rotates up to 40% easier than a traditional I-Beam Jib

- Less deflection for easier load control and positioning

Articulating Jib Cranes Free Standing

This versatile crane can move loads around corners, reach into machines or doorways, and swing under obstructions. This crane is perfect in applications that require an operator to rotate the jib in close to the pivot point. Capacities from 150 lbs. to 2000 lbs. with spans up to 16 ft.

- Floor mounted for easy installation/relocation

- Available in capacities from 150-2000 lbs. and spans up to 16 ft.

- 360� rotation at both pivot points (optional)

- Suited for applications where loads need to be positioned around obstructions, through doorways, or close to a free standing mast or building column.

- Effortless rotation

- Can be used with hook mounted lifting devices (electric, air or vacuum)

Articulating Jib Cranes Ceiling Mounted

This versatile crane can move loads around corners, reach into machines or doorways, and swing under obstructions. This crane is perfect in applications that require an operator to rotate the jib in close to the pivot point. Capacities from 150 lbs. to 2000 lbs. with spans up to 16 ft.

- Ceiling mounted for a clear work area with no floor obstructions

- Available in capacities from 150-2000 lbs. and spans up to 16 ft.

- 360� at both pivot points (optional)

- Can be mounted to a platform supported from a Gorbel Work Station Bridge Crane to allow the jib to swing under an obstruction or outside the normal coverage of a bridge crane

- Platform mounting can deliver the benefits or an articulating jib to multiple work cells

- Effortless rotation

- Can be used with hook mounted lifting devices (electric, air, or vacuum)

Articulating Jib Cranes Wall/Column Mounted

This versatile crane can move loads around corners, reach into machines or doorways, and swing under obstructions. This crane is perfect in applications that require an operator to rotate the jib in close to the pivot point. Capacities from 150 lbs. to 2000 lbs. with spans up to 16 ft.

- Wall mounted or column mounted

- Available in capacities from 150-2000 lbs. and spans up to 16 ft.

- 200� rotation on primary boom.

- Suited for applications where maneuvering around obstacles or swinging under obstructions is necessary

- Easy Rotation

- Easy Installation

I-Beam Jib Cranes Free Standing

Gorbel's I-beam Jibs are ideal for heavier loads from 1 to 5 tons (heavier capacities available, contact the factory). They are also available in motorized or manual rotation.

- Floor-mounted or insert style.

- Capacities from 1/4 ton to 5 tons, with spans up to 20 feet.

- Versatile cranes well-suited for use beneath traveling cranes, in open areas where they serve several work areas, in outdoor applications such as loading docks, and in machining and assembly operations.

- Utilize I-beam boom assemblies for heavier capacities and longer spans.

I-Beam Jib Cranes Wall Cantilever

Gorbel's I-beam Jibs are ideal for heavier loads from 1 to 5 tons (heavier capacities available, contact the factory). They are also available in motorized or manual rotation.

- Used instead of a wall bracket jib crane when headroom is at a premium.

- Provide hoist coverage for individual use in bays, along walls or columns, and as supplements to an overhead crane or monorail system.

- Capacities from 1/4 ton to 5 tons, with spans up to 20 feet.

- Utilize I-beam boom assemblies for heavier capacities and longer spans.

I-Beam Jib Cranes Wall Bracket

Gorbel's I-beam Jibs are ideal for heavier loads from 1 to 5 tons (heavier capacities available, contact the factory). They are also available in motorized or manual rotation.

- Economically provide hoist coverage for individual use in bays, along walls or columns, or as supplements to an overhead crane or monorail system.

- Capacities from 1/4 ton to 5 tons, with spans up to 30 ft.

- Require a structurally adequate wall or column to support the jib.

- Require sufficient clearance above the boom throughout its arc to accommodate the tie rod suspension.

- Utilize I-beam boom assemblies for heavier capacities and longer spans.

I-Beam Jib Cranes Mast Type

Gorbel's I-beam Jibs are ideal for heavier loads from 1 to 5 tons (heavier capacities available, contact Milwaukee Crane). They are also available in motorized or manual rotation.

- Provide for dramatically reduced forces to supporting structures.

- Floor-supported, top-stabilized cranes capable of 360� rotation via a top and bottom bearing assembly.

- Typically do not require special foundations.

- Capacities from 1/4 ton to 5 tons, with heights up to 20 ft. and spans up to 20 ft.

- Full Cantilever and Drop Cantilever styles.

- Utilize I-beam boom assemblies for heavier capacities and longer spans.

I-Beam Jib Cranes Motorized

- Available as Free Standing, Wall Cantilever, Wall Bracket, and Mast Type series.

- The Retrofit Traction Drive Kit will fit any manufacturer's free-standing jibs with box style head assembly. The kit makes it possible to update an existing free-standing jib crane with motorized power as a cost-effective way to solve workers' compensation or safety problems.

- Utilize I-beam boom assemblies for heavier capacities and longer spans.

Contact Milwaukee Crane for more information and pricing.

Steel Gantry Cranes Fixed Height

Gorbel's Fixed Height Steel Gantry Cranes provide an economical way to lift materials anywhere in a facility. Gorbel's heavy duty end frame design with square tubing uprights, knee braces and channel base provides stable lifting and movement.

- Capacities from 1 to 5 Ton, with spans up to 30' and HUB's to 20'.

- The non-marking durable polyurethane casters provide low rolling resistance for easy movement.

- Bolted beam to upright connection to ensure that beam does not dislodge.

- Pre-engineered for use with powered hoists.

Options:

- Four position swivel locking casters

- V-groove casters for track mounted cranes

- Steel casters

- Casters with wheel brakes

Steel Gantry Cranes Adjustable Height

Gorbel's Adjustable Steel Gantry Crane provides the most flexible lifting solution of any style jib crane. The adjustable gantry can be moved to almost any location and can be easily adjusted to provide different lifting heights.

- Capacities from 1 to 5 Ton, with spans up to 30' and HUB's to 20'.

- All bolted connections between the beam and uprights

Options:

- Four position swivel locking casters

- V-groove casters for track mounted cranes

- Steel casters

- Casters with wheel brakes

- Spanco Gantry Cranes

- TC American Patent Track

TC American Patented Track Monorails & Cranes

Twin Cities Monorail is now TC American

Monorail systems are commonly used in manufacturing and warehousing of items. Monorails can be used to bring products through the entire manufacturing process without the need for it to ever touch the ground. Systems can be as simple as a traveling hoist, or as complex as a custom engineered crane. Monorails have the advantage over ground based systems in that they take up no floor space allowing you the most productivity from every square foot of your facility. Monorail opens a whole new world of possibility to the savvy plant manager.

Patented Track and Monorail Components

200 Series 2.00" Rail:

These light capacity cranes and monorails easily handle loads up to two tons. They offer the ultimate in flexibility, versatility, and economy. The 200 Series cranes and monorails deliver maximum strength and minimum roll resistance. They can be hand propelled, gravity or motor driven.

325 Series 3.25" Rail:

The demands of industry for a broad line of hard working material handling equipment is the basis behind our 325 Series. It's complete, versatile, and expandable. It's the right move for transporting and positioning loads to 20 tons or greater. The 325 series rail systems are now also available on the Spanmaster� Work Center Cranes.

400 Series 4.00" Rail:

The 400 Series is equally balanced between weight and strength. The 400 Series equipment can be configured to meet any complicated track layout. The 400 Series is compatible with most older 4" systems.

450 Series 4.50" Rail:

Extra heavy loads, extra duty cycles and extra long spans require the 450 Series. Structurally engineered to assure practical overhead materials handling, the 450 Series is capable of moving loads up to 40 tons.

Trolleys:

The design of the TC/American trolley utilizes a hanger system that allows for a small amount of movement reducing stress on the trolley wheels increasing the life of the trolley and rail while improving the overall smoothness of the movement.

Drives:

TC/American manufactures a wide variety of electrically powered drives to help transport loads on monorail systems. Drives use hardened steel wheels, heavy duty gearing and motors providing years of dependable service with minimal maintenance.

Interlocks:

TC/American crane and monorail systems can be joined end to end through the use of interlocks. This gives you the ability to transfer loads from one system to another without the need to change from one hoist to another.

Cranes:

TC/American has the ability to manufacture a wide variety of overhead cranes. Our cranes use the same Patented Track technology that our monorail systems use ensuring serviceability and long life.

Curves:

TC/American can bend the Patented Track rail into a curved section allowing your system to travel unobstructed around corners and curves without any need to transfer loads.

Switches:

Switches allow the option of switching trolleys, tractors and hoists between two or three different lines on a monorail system. This eliminated the need to transfer loads from one hoist to another in the transport process.

Please contact Milwaukee Crane's expert staff for applications assistance for TC American monorail crane syystems.

TC American 200 Series Monorail Components

The 200 Series is the lightest weight and most versatile of the monorails. The 200 Series rail is a bolted two piece design with a lower rail width of 2 inches. This design allows for easy installation and modification. The 200 Series Rail is also available in a girder rail design. By adding this backbone to the rail it enables it to handle heavier loads and requires fewer supports so that it can span greater distances.

The 200 Series Monorail can be formed into curves on site allowing you to route the rail nearly anywhere you desire. A system of Switches and Interlocks can be added to the rail to allow you to interconnect your rail systems for the easy movement of goods from one station or department to another. This system eliminates the need to set items on the ground because one hoist can travel from station to station while under load.

Two Four and Eight Wheel Articulating Trolleys with drop forged wheels ensures you can handle loads ranging from 250 to 5600 lbs. These trolleys utilize a heavy structural load bar that rides under rail on trolley yokes allowing the trolley to swivel and articulate freely. A series of cranes can be fitted to your 200 series system that are available in hand push, hand chain, air or electrically operated design.

TC American 325 Series Monorail Components

The demands of industry for a broad line of hard working material handling equipment is the basis behind our 325 Series. Its complete, versatile, and expandable, the right move for transporting and positioning loads up to 20 tons or more.

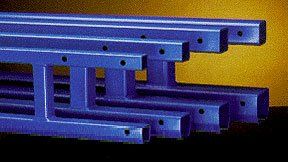

325 Series Rail is a three part Patented Track fabrication consisting of a high carbon manganese steel rolled T-section, an A36 steel web plate and top flange. These three parts are fused together during our state of the art welding process resulting in uniform rail that is straight and true from section to section. The rail is available in a range of sizes from 8 � to 40 inches deep depending upon your needs.

A system of interlocks and switches keeps you on track while transferring from one rail system to another. This system of interlocks and switches facilitates the easy transfer from one station to another without the need to switch carriers.

Any number of cranes can be mounted to your rail system Single and double girder, truss, or have a specialty crane designed for your specific application.

The 325 Series rail can be electrified through the use of TC/American's shielded conductor bars attached to the rail. These vinyl covered conductor bars offer safety, excellent conductivity and long wear.

Drive Units for the 325 Series are high torque heavy duty assemblies for hoist, carrier and crane drives. Drive motors range in power from 1/2 hp to 5 hp. Single, dual or variable speed drive systems are also available with speed ranges from 28 FPM to 600 FPM in AC or DC configuration.

The 325 series precision made articulating trolleys and wheels are designed for long service life and maximum rolling efficiency. Wheels are drop forged and ride on regreaseable or prelubricated sealed bearings. Wheel treads are induction hardened, providing years of outstanding service. Trolley yokes are adaptable to nearly any industrial application and built to handle years of service.

The 325 Series with the Patented Track design is also available in the Spanmaster� Work Station Crane design. Spanmaster� systems are versatile and can be either building-supporting or self-supporting.

TC American 400 Series Monorail Components

Used to replace, and complement existing systems. It is also used in new installations. The 400 Series is designed around a 3 piece welded design. 400 series systems transport loads up to 10 tons. Equally balanced between weight and strength, 400 series equipment can be flexibly applied to meet any complicated track layout.

The 400 series can be bent to create a wide variety of curves or connected to a series of switches to help you position your loads where you need them without the need to switch trolleys.

Like all TC/American monorail, a variety of trolleys are available for use on the 400 series rail. These heavy duty articulating trolleys are available with either flanged or flangeless wheels. Flangeless wheels in combination with side rollers reduce wheel friction to a minimum keeping the trolley in perfect alignment for high speed travel minimizing wear to track flanges on straight or curved sections.

Monotractors can be added to move loads of up to 10 tons with ease using precision hardened, duty rated helical gears running in oil to power a 12" solid rubber tire. These are operated by push button or radio control.

Pneumatic and electrical service can be added to power hoists and accessories eliminating hanging cords and hoses.

TC American 450 Series Monorail Components

Extra-heavy loads, duty cycles and extra long spans require the TC/American 450 Series Cranes and Monorails. Structurally engineered to assure practical overhead material handling, the 450 Series is capable of moving loads of 40 tons or more.

The rail is a Patented Track, three part fabrication, similar to the 325 series rail. However, the high carbon manganese steel rolled T-section has a tread size of 4 � inches wide and 1 1/8 inches thick! This gives the 450 series high wear resistance, and long tread life.

The 450 Series precision made articulating trolleys and wheels are designed for long service life and maximum rolling efficiency. Wheels are drop forged and ride on regreaseable or prelubricated sealed bearings, and wheel treads are induction hardened providing outstanding service over the years. Trolley yokes are adaptable to nearly any industrial application and built to handle years of service.

Track switches offer a standard 10 ton capacity glide switch that are power or chain operated. Although engineered and built for extra heavy-duty applications, switches are compact, requiring minimum headroom.

The 450 Series drive unit is specifically designed for heavy-duty crane drive and monorail applications. Machined drop forged steel 9" trolley wheels have hardened treads and guide rollers for added endurance and stability. Single, dual, and variable speeds from 35 FPM to 600 FPM are available from 1 � to 5 HP. AC and DC configurations are available.

Single and double girder cranes with 4 and 8 wheel end trucks are standard. Wheel bases extend from 72" to 108", depending upon capacity. All cranes are custom engineered and fabricated to the job requirements.

Components

ELECTRIFICATION

- Electromotive

Electrification Products for Cranes

Milwaukee Crane has the right electrification product for you

Milwaukee Crane has world class crane and hoist electrification systems for new crane systems, crane rebuilds, crane retrofits and crane service.

The most frequently installed and serviced types of electrification are:

- Crane Bridge

- Cable Reel

- Shielded Bar

- Festoon Cable

- Monorail and Runway

- Cable Reel

- Shielded Bar

- Festoon Cable

Milwaukee Crane offers these fine product lines for your electrification needs:

You can view detailed information at the above links.

Please contact Milwaukee Crane's expert staff for applications assistance with electrification products.

Electromotive Crane Components

Crane Controls, Electrification, Inverter Drives and More

Electromotive Systems, a Magnetek company, is the world's leading designer and manufacturer of electrification and control products for the overhead material handling industry.

- Electromotive Systems IMPULSE� Series crane controls have a proven track record of providing unmatched performance and reliability to the overhead material handling industry.

- Electrification Electromotive Systems is an industry leader in providing precision electrification products for overhead material handling equipment.

- Engineered Systems Electromotive Systems offers a broad range of control, application & system solutions for overhead material handling.

- Contract Services Electromotive contract services offer the facilities and know-how to cost-effectively manufacture control systems to meet your exact specifications.

See more information on

Electromotive products:

Motion Controls

A combination of extensive application experience and leading-edge products provides the ultimate solution for overhead motion control.

Remote Radio Controls

PulseStar� Remote Radio Controls set a whole new standard in radio remote crane controls.

Electrification

Electromotive Systems is an industry leader in providing precision electrification products for overhead material handling equipment.

Please contact Milwaukee Crane's expert staff for applications assistance with Electromotive products, Engineered Systems and Contract Services.

Motion Controls

IMPULSE� AC Crane Controls

Electromotive Systems IMPULSE� Series crane controls have a proven track record of providing unmatched performance and reliability to the overhead material handling industry.

OmniPulse™ DC Digital Crane Controls

Electromotive Systems introduces OmniPulse Digital Crane Controls, the only microprocess controlled DC drive designed to work specific with a DC power input source.

MAC™•2000

Electromotive Systems introduces MAC™•2000, a reduced voltage soft start for applications needing cost-efficient motor control.

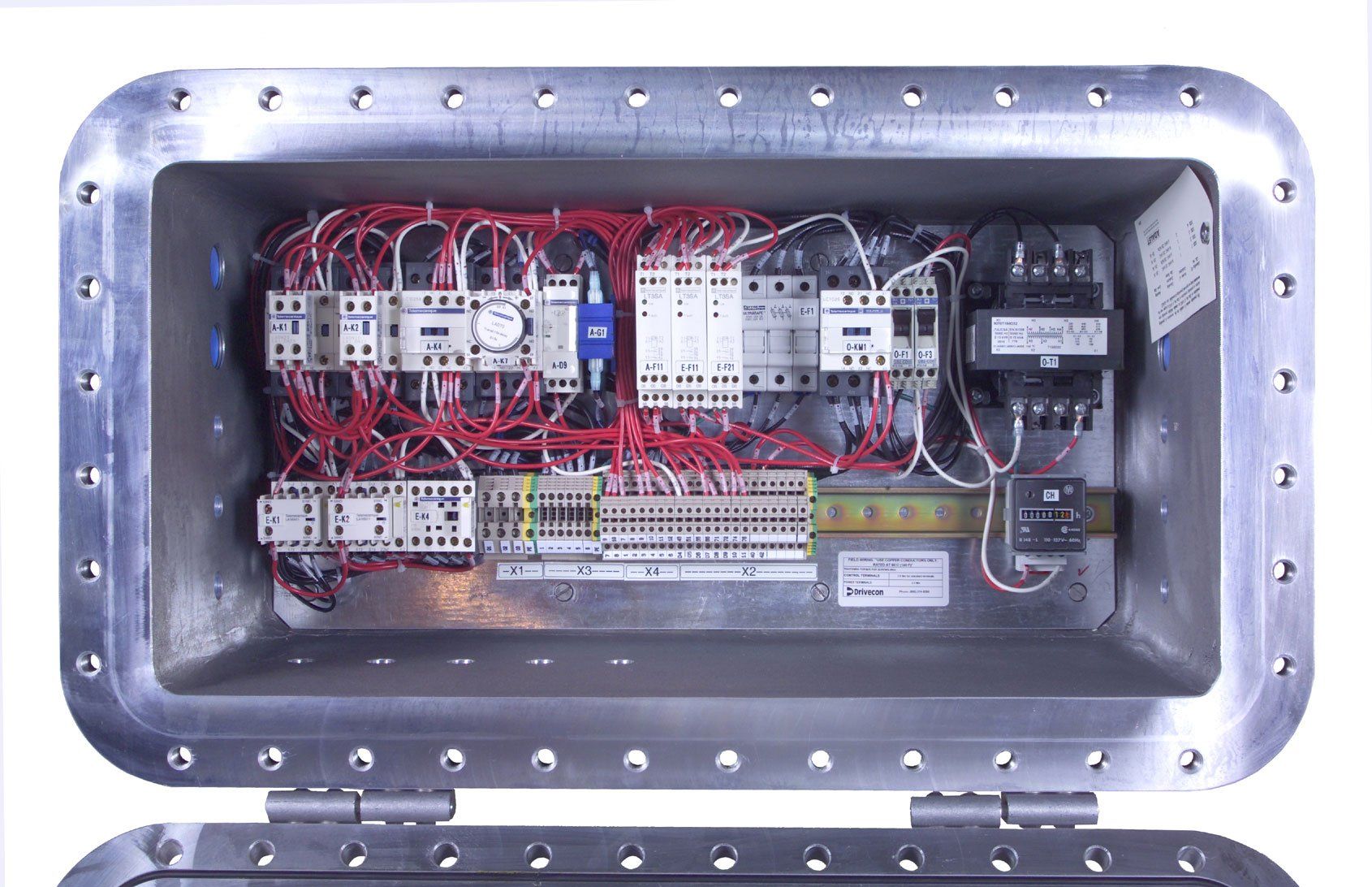

TCONTROLS�

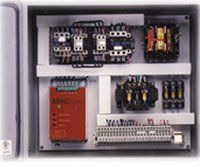

TCONTROLS� Complete Crane Control Panels feature all the components needed to provide complete motor control for bridge, trolley, hoisting or combined overhead crane motions.

ReFlx™

The Electromotive Systems' ReFlx™ 120 and 120 "Plus" distance detection and collision avoidance systems are designed with reliability and economy in mind.

Motors

Electromotive Systems' inverter duty motors have been designed to meet the demands of crane/hoist applications, where premium construction and performance are a must.

Radio Controls

PulseStar� Systems

Electromotive Systems has achieved a whole new level of performance, reliability and value with our technologically advanced line of PulseStar� Remote Crane Controls.

Transmitters

Lightweight, durable transmitters for PulseStar� Remote Crane Controls.

Electrification

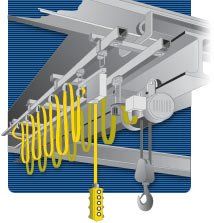

Electromotive Festoon Systems and Cable

ELECTROMOTIVE™ Festoon Systems and Cable provide an efficient method of delivering power and control to overhead material handling equipment.

SBP Pendant Pushbutton Stations

Electromotive Systems' SBP� Pendant Pushbutton Stations provide optimum control and performance with less effort and fatigue than traditional pendants.

SBP2 Pendant Push-button Stations

The new Electromotive Systems' SBP2 features an ergonomic design that delivers improved control, performance and more operator comfort.

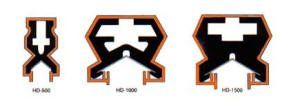

ELECTROBAR�, ELECTROBAR ELITE�, ELECTROBAR� FS And FABA� Enclosed Conductor Bar Systems

ELECTROBAR�, ELECTROBAR ELITE�, ELECTROBAR� FS And FABA� Enclosed Conductor Bar Systems provide an array of options and accessories for the electrification of overhead material handling equipment.

Please contact the experts at Milwaukee Crane for assistance with Electromotive products and services.

IMPULSE��P3 Series 2 AC Crane Control

The Electromotive Systems IMPULSE��P3 Series 2 crane control gives operators total command over crane and hoist movements.

IMPULSE��G+ Series 2 AC Crane Control

Electromotive Systems IMPULSE��G+ Series 2 crane controls have a proven track record of providing unmatched performance and reliability in the overhead material handling industry.

IMPULSE��VG+ Series 2 AC Crane Control

Featuring our exclusive crane and hoist software, IMPULSE��VG+ Series 2 third generation controls offer many features designed for ease of use and enhanced safety.

MAC��2000

Motor Acceleration Control

A reduced voltage soft start for applications needing cost-efficient motor control.

Versatility, reliability and value are the three words that best describe Electromotive Systems' MAC��2000 motor acceleration control.

Versatile

A common unit can be utilized for single- and two-speed applications in the 230V/460V design for up to 15.2 amps. The 575V model is similarly designed with single- and two-speed capability in a common unit for up to 15.2 amps.

Reliable

MAC��2000 has been designed specifically to recognize the high duty cycle start, stop and jogging conditions that are associated with overhead material handling applications.

Value