Oregon and the Northwest's Best Crane Builder Since 1945

Types of Cranes Provided:

- Top-Running Single Girder

- Top-Running Double Girder

- Under-Running Single Girder

- Under-Running Double Girder

- Jib Cranes

- Freestanding Workstation Cranes

- Light capacity ergonomic cranes

- Aluminum bridges for ergonomic cranes

Types of Controls Available:

- 1-Speed

- 2-Speed

- Variable Frequency

- Variable Speed Control

- Pendant Control

- Radio Control

- Cab Control

- Air Powered

For the Following Applications:

- Standard Industrial Service

- Indoor Service

- Outdoor Service

- Heavy to Severe Service

- Hazardous Environments

Typical Dimensions & Specifications:

Underhung Up to 10 Tons

|

Under Hung Single Girder Bridge Crane -- Floor Operated |

|||||||||||||||

|

CAPACITY |

B or |

HEADROOM |

BTM OF |

* |

MAX. |

||||||||||

| SPEED |

SPAN |

B1 |

LOW |

STD. |

BRIDGE |

RUNWAY |

WHEEL |

||||||||

| RANGE |

A |

MIN. |

C |

E |

F |

F |

G |

H |

M |

N |

Y |

Z |

AA |

BEAM |

LOAD lb/pr |

|

1 |

20' |

10 1/2 |

10 1/2 |

6 3/4 |

19 |

23 |

24 |

17 |

4'-6 |

3'-9 |

3'-4 |

3'-4 |

1'-1 1/2 |

MIN. |

1900 |

|

TON 10 TO 28 FPM |

30' |

10 1/2 |

10 1/2 |

6 3/4 |

19 |

23 |

24 |

17 |

4'-6 |

3'-9 |

3'-4 |

3'-4 |

1'-1 1/2 |

10"@25.4 |

2220 |

|

40' |

10 1/2 |

10 1/2 |

7 3/4 |

19 |

23 |

24 |

17 |

6'-3 |

3'-9 |

3'-11 1/2 |

3'-11 1/2 |

1'-4 1/2 |

MAX. |

2520 |

|

|

50' |

10 1/2 |

10 1/2 |

7 3/4 |

19 |

23 |

24 |

17 |

7'-6 |

3'-9 |

4'-7 |

4'-7 |

1'-10 1/2 |

20"@66 |

3000 |

|

|

60' |

10 1/2 |

10 1/2 |

7 3/4 |

19 |

23 |

24 |

17 |

7'-6 |

3'-9 |

4'-7 |

4'-7 |

1'-10 1/2 |

3250 |

||

|

2 |

20' |

10 1/2 |

10 1/2 |

6 3/4 |

19 |

28 |

24 |

17 |

4'-6 |

4'-0 |

3'-4 |

3'-4 |

1'-1 1/2 |

MIN. |

3175 |

|

TON 14 TO 21 FPM |

30' |

10 1/2 |

10 1/2 |

6 3/4 |

19 |

28 |

24 |

17 |

4'-6 |

4'-0 |

3'-4 |

3'-4 |

1'-4 1/2 |

10"@25.4 |

3550 |

|

40' |

10 1/2 |

10 1/2 |

7 3/4 |

19 |

28 |

24 |

17 |

6'-3 |

4'-0 |

3'-11 1/2 |

3'-11 1/2 |

1'-10 1/2 |

MAX. |

4050 |

|

|

50' |

10 1/2 |

10 1/2 |

7 3/4 |

19 |

28 |

24 |

17 |

7'-6 |

4'-0 |

4'-7 |

4'-7 |

1'-10 1/2 |

20"@66 |

4550 |

|

|

60' |

10 1/2 |

10 1/2 |

7 3/4 |

19 |

28 |

24 |

17 |

7'-6 |

4'-0 |

4'-7 |

4'-7 |

2'-1 1/2 |

5200 |

||

|

3 |

20' |

10 1/2 |

10 1/2 |

6 3/4 |

26 |

29 |

35 |

18 |

4'-6 |

4'-5 |

3'-4 |

3'-4 |

1'-7 1/2 |

MIN. |

4600 |

|

TON 11 TO 24 FPM |

30' |

10 1/2 |

10 1/2 |

6 3/4 |

26 |

3

29 |

35 |

18 |

4'-6 |

4'-5 |

3'-4 |

3'-4 |

1'-10 1/2 |

10"@25.4 |

4950 |

|

40' |

10 1/2 |

10 1/2 |

7 3/4 |

26 |

29 |

35 |

18 |

6'-3 |

4'-5 |

3'-11 1/2 |

3'-11 1/2 |

1'-10 1/2 |

MAX. |

5100 |

|

|

50' |

10 1/2 |

10 1/2 |

7 3/4 |

26 |

29 |

35 |

18 |

7'-6 |

4'-5 |

4'-7 |

4'-7 |

2'-1 1/2 |

20"@66 |

6020 |

|

|

60' |

12 |

12 |

9 3/4 |

26 |

29 |

35 |

18 |

7'-6 |

4'-5 |

4'-9 |

4'-9 |

2'-1 1/2 |

6520 |

||

|

5 |

20' |

10 1/2 |

10 1/2 |

6 3/4 |

28 |

41 |

37 |

19 |

4'-6 |

4'-6 |

3'-4 |

3'-4 |

1'-7 1/2 |

MIN. |

7080 |

|

TON 15 TO 28 FPM |

30' |

10 1/2 |

10 1/2 |

7 3/4 |

28 |

41 |

37 |

19 |

4'-6 |

4'-6 |

3'-4 |

3'-4 |

1'-10 1/2 |

12"@40.8 |

7400 |

|

40' |

10 1/2 |

10 1/2 |

7 3/4 |

28 |

41 |

37 |

19 |

6'-3 |

4'-6 |

3'-11 1/2 |

3'-11 1/2 |

2'-1 1/2 |

MAX. |

7920 |

|

|

50' |

12 |

12 |

9 3/4 |

28 |

41 |

37 |

19 |

7'-6 |

4'-6 |

4'-9 |

4'-9 |

2'-1 1/2 |

20"@66 |

8500 |

|

|

60' |

12 |

12 |

9 3/4 |

28 |

41 |

37 |

19 |

7'-6 |

4'-6 |

4'-9 |

4'-9 |

2'-7 1/5 |

9380 |

||

|

7 1/2 |

20' |

12 |

12 |

9 3/4 |

30 |

48 |

41 |

24 |

4'-6 |

5'-0 |

3'-6 |

3'-6 |

2'-1 1/2 |

MIN. |

10400 |

|

TON 14 TO 19 FPM |

30' |

12 |

12 |

9 3/4 |

30 |

48 |

41 |

24 |

4'-6 |

5'-0 |

3'-6 |

3'-6 |

2'-1 1/2 |

20"@66 |

10760 |

|

40' |

12 |

12 |

9 3/4 |

30 |

48 |

41 |

24 |

6'-3 |

5'-0 |

4'-1 1/2 |

4'-1 1/2 |

2'-1 1/2 |

MAX. |

11280 |

|

|

50' |

12 |

12 |

9 3/4 |

30 |

48 |

41 |

24 |

7'-6 |

5'-0 |

4'-9 |

4'-9 |

2'-7 1/2 |

24"@121 |

12100 |

|

|

60' |

12 |

12 |

11 3/4 |

30 |

48 |

41 |

24 |

8'-6 |

5'-0 |

5'-3 |

5'-3 |

2'-10 1/2 |

12950 |

||

|

10 |

20' |

12 |

12 |

9 3/4 |

37 |

52 |

47 |

27 |

4'-6 |

5'-4 |

3'-6 |

3'-6 |

2'-1 1/2 |

MIN. |

13300 |

|

TON 14 TO 19 FPM |

30' |

12 |

12 |

9 3/4 |

37 |

52 |

47 |

27 |

4'-6 |

5'-4 |

3'-6 |

3'-6 |

2'-1 1/2 |

20"@85 |

13700 |

|

40' |

12 |

12 |

9 3/4 |

37 |

52 |

47 |

27 |

6'-3 |

5'-4 |

4'-1 1/2 |

4'-1 1/2 |

2'-4 1/2 |

MAX. |

14250 |

|

|

50' |

12 |

12 |

9 3/4 |

37 |

52 |

47 |

27 |

7'-6 |

5'-4 |

4'-9 |

4'-9 |

2'-10 1/2 |

24"@121 |

15150 |

|

|

60' |

12 |

12 |

11 3/4 |

37 |

52 |

47 |

27 |

8'-6 |

5'-4 |

5'-3 |

5'-3 |

3'-1 1/2 |

16000 |

||

|

DIMENSIONS IN INCHES UNLESS OTHERWISE NOTED |

|||||||||||||||

| Notes: |

|||||||||||||||

Top Running Up to 10 Tons

| Top Riding Single Girder Bridge Crane -- Floor Operated |

|||||||||||||||

|

CAP. & |

HEADROOM |

BTM OF |

MAX. |

||||||||||||

|

SPEED |

SPAN |

LOW |

STD. |

S |

BRIDGE |

RUNWAY |

WHEEL |

||||||||

|

RANGE |

A |

B |

C |

F |

F |

G |

H |

M |

N |

MIN. |

Y |

Z |

AA |

RAIL # |

LOAD |

|

1 |

20' |

1'-4 1/2 |

5 |

19 |

23 |

36 |

29 |

4'-6 |

3'-9 |

7 |

3'-1 |

3'-1 |

4 |

25 |

1950 |

|

TON 10 TO 28 FPM |

30' |

1'-4 1/2 |

5 |

19 |

23 |

36 |

29 |

4'-6 |

3'-9 |

7 |

3'-1 |

3'-1 |

4 |

25 |

2350 |

|

40' |

1'-7 1/2 |

5 |

19 |

23 |

36 |

29 |

6'-3 |

3'-9 |

7 |

3'-11 1/2 |

3'-11 1/2 |

1 |

25 |

2700 |

|

|

50' |

2'-1 1/2 |

5 |

19 |

23 |

36 |

29 |

7'-6 |

3'-9 |

7 |

4'-7 |

4'-7 |

0 |

25 |

3200 |

|

|

60' |

2'-1 1/2 |

5 |

19 |

23 |

36 |

29 |

8'-6 |

3'-9 |

7 |

5'-1 |

5'-1 |

0 |

25 |

3550 |

|

|

2 |

20' |

1'-4 1/2 |

5 |

19 |

28 |

36 |

29 |

4'-6 |

4'-0 |

7 |

3'-1 |

3'-1 |

4 |

25 |

3300 |

|

TON 14 TO 21 FPM |

30' |

1'-7 1/2 |

5 |

19 |

28 |

36 |

29 |

4'-6 |

4'-0 |

7 |

3'-1 |

3'-1 |

4 |

25 |

3600 |

|

40' |

2'-1 1/2 |

5 |

19 |

28 |

36 |

29 |

6'-3 |

4'-0 |

7 |

3'-11 1/2 |

3'-11 1/2 |

1 |

25 |

4000 |

|

|

50' |

2'-1 1/2 |

5 |

19 |

28 |

36 |

29 |

7'-6 |

4'-0 |

7 |

4'-7 |

4'-7 |

0 |

25 |

4500 |

|

|

60' |

2'-4 1/2 |

5 |

19 |

28 |

36 |

29 |

8'-6 |

4'-0 |

7 |

5'-1 |

5'-1 |

0 |

25 |

5100 |

|

|

3 |

20' |

1'-10 1/2 |

5 |

26 |

29 |

47 |

30 |

4'-6 |

4'-5 |

7 |

3'-1 |

3'-1 |

2 |

25 |

3700 |

|

TON 11 TO 24 FPM |

30' |

2'-1 1/2 |

5 |

26 |

29 |

47 |

30 |

4'-6 |

4'-5 |

7 |

3'-1 |

3'-1 |

0 |

25 |

4850 |

|

40' |

2'-1 1/2 |

5 1/2 |

26 |

29 |

47 |

30 |

6'-3 |

4'-5 |

7 1/2 |

3'-11 1/2 |

3'-11 1/2 |

0 |

25 |

5300 |

|

|

50' |

2'-4 1/2 |

5 1/2 |

26 |

29 |

47 |

30 |

7'-6 |

4'-5 |

7 1/2 |

4'-7 |

4'-7 |

0 |

30 |

5800 |

|

|

60' |

2'-4 1/2 |

5 1/2 |

26 |

29 |

47 |

30 |

8'-6 |

4'-5 |

7 1/2 |

5'-1 |

5'-1 |

0 |

30 |

6300 |

|

|

5 |

20' |

1'-10 1/2 |

5 1/2 |

28 |

41 |

49 |

31 |

4'-6 |

4'-6 |

7 1/2 |

3'-1 |

3'-1 |

2 |

30 |

6850 |

|

TON 15 TO 28 FPM |

30' |

2'-1 1/2 |

5 1/2 |

28 |

41 |

49 |

31 |

4'-6 |

4'-6 |

7 1/2 |

3'-1 |

3'-1 |

0 |

30 |

7200 |

|

40' |

2'-4 1/2 |

5 1/2 |

28 |

41 |

49 |

31 |

6'-3 |

4'-6 |

7 1/2 |

3'-11 1/2 |

3'-11 1/2 |

0 |

30 |

7700 |

|

|

50' |

2'-4 1/2 |

6 |

28 |

41 |

49 |

31 |

7'-6 |

4'-6 |

8 |

4'-7 |

4'-7 |

0 |

40 |

8300 |

|

|

60' |

2'-10 1/2 |

6 |

28 |

41 |

49 |

31 |

8'-6 |

4'-6 |

8 |

5'-1 |

5'-1 |

0 |

40 |

9100 |

|

|

7 1/2 |

20' |

2'-1 1/2 |

6 |

30 |

48 |

53 |

36 |

4'-6 |

5'-0 |

8 |

3'-1 |

3'-1 |

5 |

40 |

9950 |

|

TON 14 TO 19 FPM |

30' |

2'-4 1/2 |

6 |

30 |

48 |

53 |

36 |

4'-6 |

5'-0 |

8 |

3'-1 |

3'-1 |

2 |

40 |

10300 |

|

40' |

2'-4 1/2 |

6 |

30 |

48 |

53 |

36 |

6'-3 |

5'-0 |

8 |

3'-11 1/2 |

3'-11 1/2 |

2 |

40 |

10800 |

|

|

50' |

2'-10 1/2 |

6 1/2 |

30 |

48 |

53 |

36 |

7'-6 |

5'-0 |

8 1/2 |

4'-9 |

4'-9 |

0 |

40 |

11650 |

|

|

60' |

3'-1 1/2 |

6 1/2 |

30 |

48 |

53 |

36 |

8'-6 |

5'-0 |

8 1/2 |

5'-3 |

5'-3 |

0 |

40 |

12600 |

|

|

10 |

20' |

2'-4 1/2 |

6 |

37 |

52 |

59 |

39 |

4'-6 |

5'-4 |

8 |

3'-3 |

3'-3 |

2 |

40 |

12700 |

|

TON 14 TO 19 FPM |

30' |

2'-4 1/2 |

6 |

37 |

52 |

59 |

39 |

4'-6 |

5'-4 |

8 |

3'-3 |

3'-3 |

2 |

40 |

13100 |

|

40' |

2'-7 1/2 |

6 1/2 |

37 |

52 |

59 |

39 |

6'-3 |

5'-4 |

8 1/2 |

3'-11 1/2 |

3'-11 1/2 |

0 |

40 |

13700 |

|

|

50' |

3'-1 1/2 |

6 1/2 |

37 |

52 |

59 |

39 |

7'-6 |

5'-4 |

8 1/2 |

4'-9 |

4'-9 |

0 |

40 |

14600 |

|

|

60' |

3'-4 1/2 |

6 1/2 |

37 |

52 |

59 |

39 |

8'-6 |

5'-4 |

8 1/2 |

5'-3 |

5'-3 |

0 |

40 |

15550 |

|

| DIMENSIONS IN INCHES UNLESS OTHERWISE NOTED |

|||||||||||||||

|

NOTES: |

|||||||||||||||

| * |

DIMENSIONS BASED ON APPROXIMATELY 25'-0" OF LIFT. DIMENSION "N" WILL VARY WITH LIFT HEIGHT. |

||||||||||||||

| * | BRIDGE AND TROLLEY SPEEDS ON FLOOR CONTROLLED CRANES ARE 80 AND 45 FPM. |

||||||||||||||

| * | OPTIONAL HOISTING SPEEDS, BRIDGE AND TROLLEY SPEEDS AND LIFTS ARE AVAILABLE. CONSULT MILWAUKEE CRANE FOR SPECIFIC DETAILS. |

||||||||||||||

| * | SPECIFICATIONS GIVEN ON THESE SHEETS ARE CURRENT AS OF DATE OF PUBLICATION. HOWEVER, MILWAUKEE RESERVES THE RIGHT TO MAKE |

||||||||||||||

| * | CHANGES AND MODIFICATIONS AS CONDITIONS WARRANT AND WITHOUT NOTICE. |

||||||||||||||

| * | DIMENSIONS AND CLEARANCES ARE NOT TO BE USED FOR CONSTRUCTION UNLESS CERTIFIED BY MILWAUKEE CRANE ENGINEERING DEPARTMENT. |

||||||||||||||

Top Running Up to 100 Tons

|

CAP. & SPEED RANGE |

Top Riding Double Girder Bridge Crane |

MAX. WHEEL LOAD |

|||||||||||||

|

SPAN A |

RUNWAY RAIL # |

||||||||||||||

|

B |

C |

F |

G |

H |

M |

N |

O |

Y&Z |

A-A |

B-B |

SPREAD |

||||

|

5 TON |

20'-0" |

3-10 1/4 |

6 |

24 |

3-10 1/2 |

3-6 1/2 |

9'-6 |

8'-2 |

6'-1.5 |

6'-3 1/4 |

0-2 |

0-9" |

6'-0 |

40 |

9,800 |

|

40'-0" |

3-10 1/4 |

6 |

24 |

3-10 1/2 |

3-6 1/2 |

9'-6 |

8'-2 |

6'-1.5 |

6'-3 1/4 |

0-2 |

0-9" |

6'-0 |

40 |

11,600 |

|

| 19 TO 30 FPM |

60'-0" |

3-10 1/4 |

6 |

24 |

3-10 1/2 |

3-6 1/2 |

9'-6 |

8'-2 |

6'-1.5 |

6'-3 1/4 |

0-8 |

1-3" |

6'-0 |

40 |

15,400 |

|

80'-0" |

4-3 1/4 |

6 |

24 |

3-10 1/2 |

3-6 1/2 |

12'-8 |

9'-10 1/2 |

7'-4 1/2 |

7'-10 1/4 |

1-9 1/2 |

- |

7'-0 |

40 |

20,600 |

|

|

100'-0" |

4-6 3/4 |

6 |

24 |

3-10 1/2 |

3-6 1/2 |

14'-4 |

10'-8 1/2 |

8'-2 1/2 |

8'-8 1/4 |

2-2 1/2 |

- |

8'-0 |

40 |

26,200 |

|

|

7 1/2 |

20'-0" |

4-2 1/4 |

6 |

30 |

3-11 1/2 |

3-8 1/2 |

9'-6 |

8'-2 |

6'-1.5 |

6'-3 1/4 |

0-2 |

0-9" |

6'-0 |

40 |

12,100 |

|

TON |

40'-0" |

4-2 1/4 |

6 |

30 |

3-11 1/2 |

3-8 1/2 |

9'-6 |

8'-2 |

6'-1.5 |

6'-3 1/4 |

0-5 |

1'-0 |

6'-0 |

40 |

14,200 |

|

60'-0" |

4-7 1/4 |

6 |

30 |

3-11 1/2 |

3-8 1/2 |

9'-6 |

8'-2 |

6'-1.5 |

6'-3 1/4 |

0-9 1/2 |

1'-4 |

6'-0 |

40 |

19,800 |

|

|

14 TO 38 |

80'-0" |

4-7 1/4 |

6 |

30 |

3-11 1/2 |

3-8 1/2 |

12'-8 |

9'-10 1/2 |

7'-4 1/2 |

7'-10 1/4 |

2-1 1/2 |

- |

7'-0 |

40 |

23,500 |

|

FPM |

100'-0" |

4-10 3/4 |

6 |

30 |

3-11 1/2 |

3-8 1/2 |

14'-4 |

10'-8 1/2 |

8'-2 1/2 |

8'-8 1/4 |

2-6 1/2 |

- |

8'-0 |

60 |

30,100 |

|

10 |

20'-0" |

4-2 1/4 |

6 |

40 |

4-4 1/2 |

3-2 1/2 |

9'-6 |

8'-2 |

6'-1.5 |

6'-3 1/4 |

0-2 |

0-9" |

6'-0 |

40 |

14,200 |

|

TON |

40'-0" |

4-2 1/4 |

6 |

40 |

4-4 1/2 |

3-2 1/2 |

9'-6 |

8'-2 |

6'-1.5 |

6'-3 1/4 |

0-5 |

1'-0 |

6'-0 |

40 |

16,500 |

|

60'-0" |

4-7 1/4 |

6 |

40 |

4-4 1/2 |

3-2 1/2 |

9'-6 |

8'-2 |

6'-1.5 |

6'-3 1/4 |

0-9 1/2 |

1'-4 |

6'-0 |

40 |

21,700 |

|

|

14 TO 31 |

80'-0" |

4-7 1/4 |

7 |

40 |

4-4 1/2 |

3-2 1/2 |

12'-8 |

9'-10 1/2 |

7'-4 1/2 |

7'-10 1/4 |

2-1 1/2 |

- |

7'-0 |

40 |

25,600 |

|

FPM |

100'-0" |

4-10 3/4 |

7 |

40 |

4-4 1/2 |

3-2 1/2 |

14'-4 |

10'-8 1/2 |

8'-2 1/2 |

8'-8 1/4 |

2-6 1/2 |

- |

8'-0 |

60 |

32,600 |

|

15 |

20'-0" |

4-2 1/4 |

6 |

42 |

4-4 1/2 |

3-2 1/2 |

11'-6 |

9'-2 |

7'-1 1/2 |

7'-3 1/4 |

0-2 |

0-9" |

8'-0 |

40 |

18,900 |

|

TON |

40'-0" |

4-2 1/4 |

6 |

42 |

4-4 1/2 |

3-2 1/2 |

11'-6 |

9'-2 |

7'-1 1/2 |

7'-3 1/4 |

0-5 |

1'-0 |

8'-0 |

40 |

21,500 |

|

60'-0" |

4-7 1/4 |

6 |

42 |

4-4 1/2 |

3-2 1/2 |

11'-6 |

9'-2 |

7'-1 1/2 |

7'-3 1/4 |

0-9 1/2 |

1'-4 |

8'-0 |

60 |

26,500 |

|

|

10 TO 20 |

80'-0" |

4-7 1/4 |

7 |

42 |

4-4 1/2 |

3-2 1/2 |

13'-8 |

10'-4 1/2 |

7'-10 1/2 |

8'-4 1/4 |

2-5 1/2 |

- |

8'-0 |

60 |

31,200 |

|

FPM |

100'-0" |

4-10 3/4 |

7 |

42 |

4-4 1/2 |

3-2 1/2 |

14'-4 |

10'-8 1/2 |

8'-2 1/2 |

8'-8 1/4 |

2-10 1/2 |

- |

8'-0 |

60 |

38,600 |

|

20 |

20'-0" |

4-2 1/4 |

7 |

46 |

5-5 1/2 |

3-8 1/2 |

11'-6 |

9'-2 |

7'-1 1/2 |

7'-3 1/4 |

0-2 |

0-9" |

8'-0 |

60 |

23,100 |

|

TON |

40'-0" |

4-2 1/4 |

7 |

46 |

5-5 1/2 |

3-8 1/2 |

11'-6 |

9'-2 |

7'-1 1/2 |

7'-3 1/4 |

0-8 |

1'-3 |

8'-0 |

60 |

26,100 |

|

60'-0" |

4-7 1/4 |

7 |

46 |

5-5 1/2 |

3-8 1/2 |

11'-6 |

9'-2 |

7'-1 1/2 |

7'-3 1/4 |

1-0 1/2 |

1'-7 |

8'-0 |

60 |

32,000 |

|

|

13 TO 23 |

80'-0" |

4-7 1/4 |

7 |

46 |

5-5 1/2 |

3-8 1/2 |

14'-0 |

10'-6 1/2 |

8'-0 1/2 |

8'-6 1/4 |

2-5 1/2 |

- |

8'-0 |

60 |

36,500 |

|

FPM |

100'-0" |

5-2 3/4 |

7 |

46 |

5-5 1/2 |

3-8 1/2 |

15'-2 |

10'-10 1/2 |

8'-4 1/2 |

9'-3 1/4 |

2-10 1/2 |

- |

8'-0 |

60 |

45,500 |

|

25 |

20'-0" |

4-2 1/4 |

7 |

51 |

5-1 1/2 |

3-10 1/2 |

11'-6 |

9'-2 |

7'-1 1/2 |

7'-3 1/4 |

0-2 |

0-9" |

8'-0 |

60 |

27,200 |

|

TON |

40'-0" |

4-2 1/4 |

7 |

51 |

5-1 1/2 |

3-10 1/2 |

11'-6 |

9'-2 |

7'-1 1/2 |

7'-3 1/4 |

0-8 |

1'-3 |

8'-0 |

60 |

30,500 |

|

60'-0" |

4-7 1/4 |

7 |

51 |

5-1 1/2 |

3-10 1/2 |

11'-6 |

9'-2 |

7'-1 1/2 |

7'-3 1/4 |

1-0 1/2 |

1'-7 |

8'-0 |

60 |

36,000 |

|

|

9 TO 18 |

80'-0" |

5-2 1/4 |

7 |

51 |

5-1 1/2 |

3-10 1/2 |

14'-6 |

10'-6 1/2 |

8'-0 1/2 |

8'-11 1/4 |

2-5 1/2 |

- |

8'-0 |

60 |

42,300 |

|

FPM |

100'-0" |

5-2 3/4 |

8 |

51 |

5-1 1/2 |

3-10 1/2 |

15'-2 |

10'-10 1/2 |

8'-4 1/2 |

9'-3 1/4 |

2-10 1/2 |

- |

8'-0 |

60 |

49,800 |

|

30 |

20'-0" |

4-5 1/4 |

7 |

63 |

5-7 1/2 |

3-10 1/2 |

13'-6 |

10'-2 |

8'-1 1/2 |

8'-3 1/4 |

0-5 |

1'-0 |

10'-0 |

60 |

32,400 |

|

TON |

40'-0" |

4-9 1/2 |

7 |

63 |

5-7 1/2 |

3-10 1/2 |

13'-6 |

10'-2 |

8'-1 1/2 |

8'-3 1/4 |

0-6 1/2 |

1-1 1/2 |

10'-0 |

60 |

35,900 |

|

60'-0" |

4-9 1/2 |

7 |

63 |

5-7 1/2 |

3-10 1/2 |

14'-0 |

10'-2 |

8'-1 1/2 |

8'-3 1/4 |

0-8 1/2 |

1'-3 |

10'-0 |

60 |

40,900 |

|

|

8 TO 15 |

80'-0" |

5-5 3/4 |

8 |

63 |

5-7 1/2 |

3-10 1/2 |

16'-7 |

11'-7 |

9'-1 |

9'-11 3/4 |

2-6 1/2 |

- |

10'-0 |

80 |

49,000 |

|

FPM |

100'-0" |

5-7 1/4 |

8 |

63 |

5-7 1/2 |

3-10 1/2 |

17'-3 |

11'-11 |

9'-5 |

10'-3 3/4 |

2-9 1/4 |

- |

10'-0 |

80 |

55,700 |

| 30 - 100 TON |

Specially Designed | ||||||||||||||

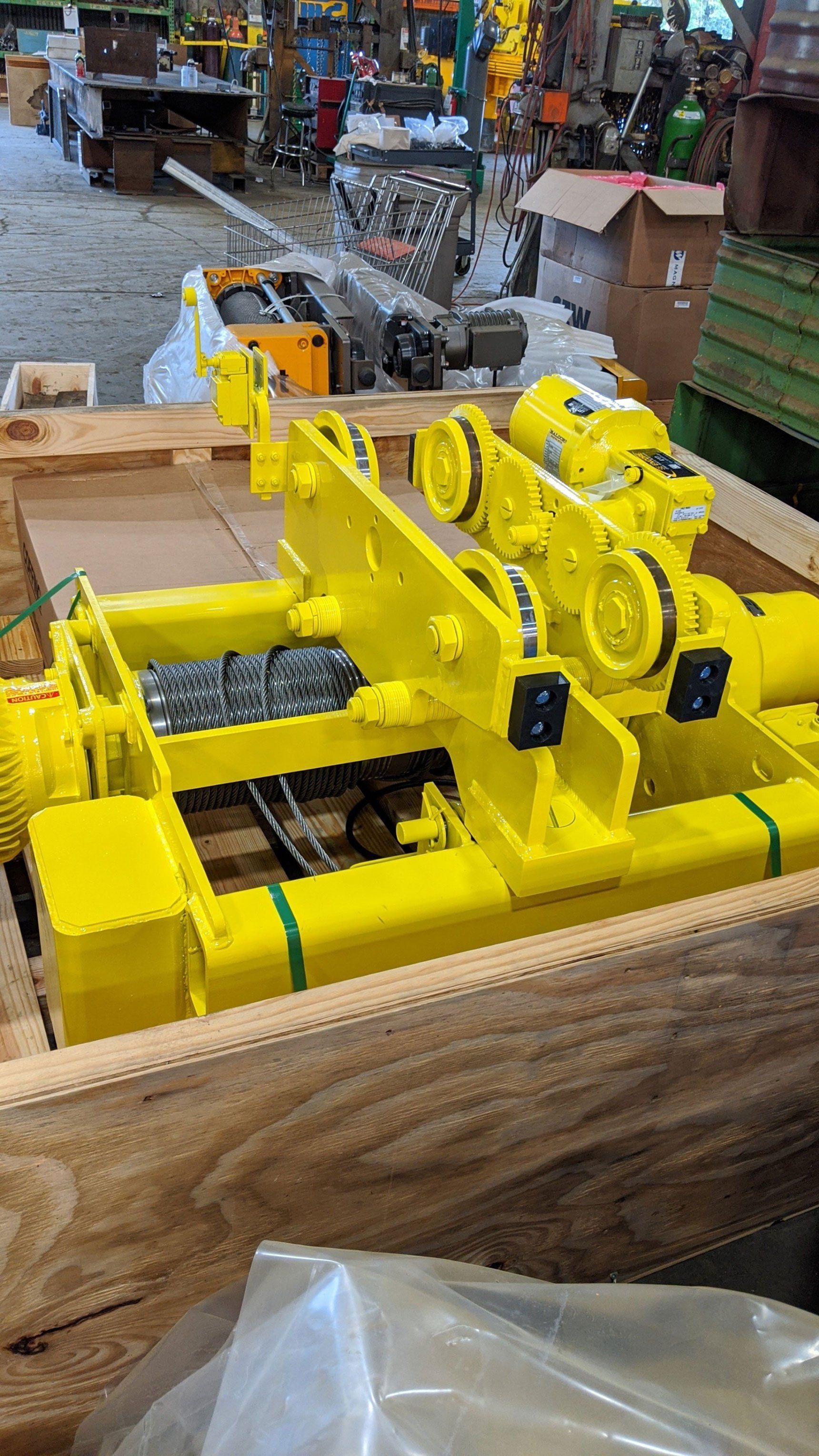

Hoists & Crane Components

- Turnkey Crane Systems: We design, manufacture and install complete overhead material handling systems and offer the best components to meet the requirements for designing and building new cranes for your specific application.

- Modernization: Modification and upgrades to your existing crane systems

- Crane & Hoist Repair Parts for all brands - the largest stock inventory in the Northwest

- Hoisting Equipment: Hoists, trolleys and accessories in stock for immediate delivery

- Ace Heavy Duty Hoists

- Budgit Hoists

- Chester Hoists

- Duct-O-Wire

- Electromotive

- Gorbel G-Force Intelligent Lifting Devices

- Ingersoll-Rand Hoists

- Insul-8

- Mondel Brakes

- Monorail Systems

- P & H Crane Parts

- Shaw Box Hoists

- Teleradio Industrial Remote Radio Controls

- Yale Hoists and Crane Components

Workstation Cranes

Crane Accessories

- Below the Hook Slings, spreader bars, lifting attachments

- Radio remote and pendant control stations

- Modernization Modification and upgrades to your existing crane systems

- Hoisting Equipment Hoists, trolleys and accessories in stock for immediate delivery

- Ergonomic Systems: Light capacity handling systems for assembly, warehouse and distribution handling

- Alpha Radio Controls

- Bushman Grabs, Spreader Bars, Powered Bottom Blocks

- Caldwell Below the Hook Accessories

- Duct-O-Wire Pendants

- Electromotive Radio Controls & Pendants

- IR Zimmerman Ergonomic Systems

- Insul-8 Pendants & Radio Controls

- Posi-Turner Below the Hook

- Univac Vacuum Lifters